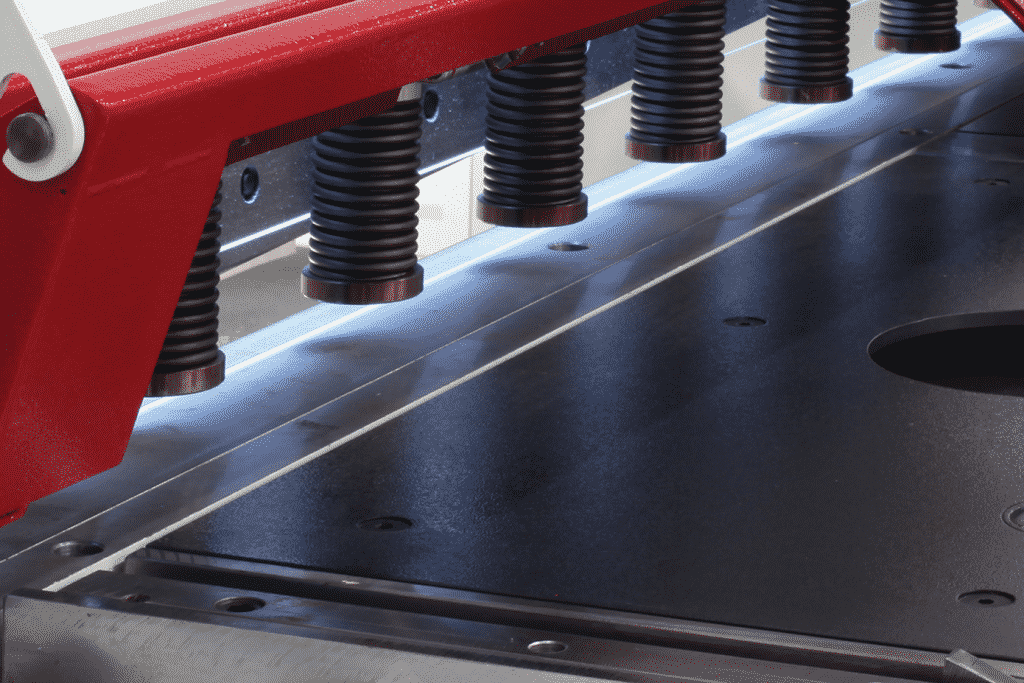

HSS Paper Cutting Knives Guillotine Blades HSS for Polar Machine

Product Introduction

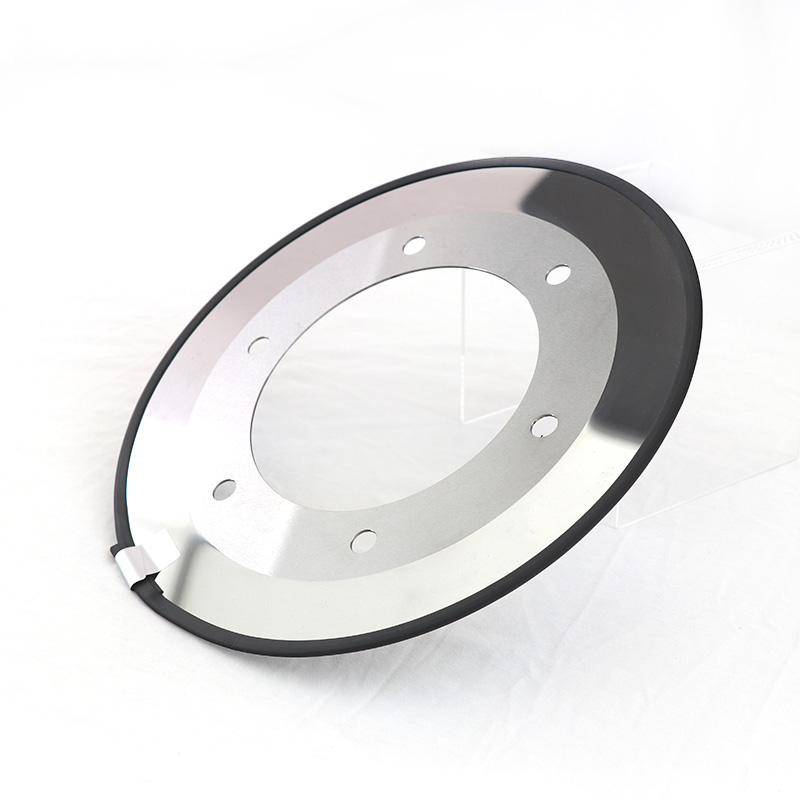

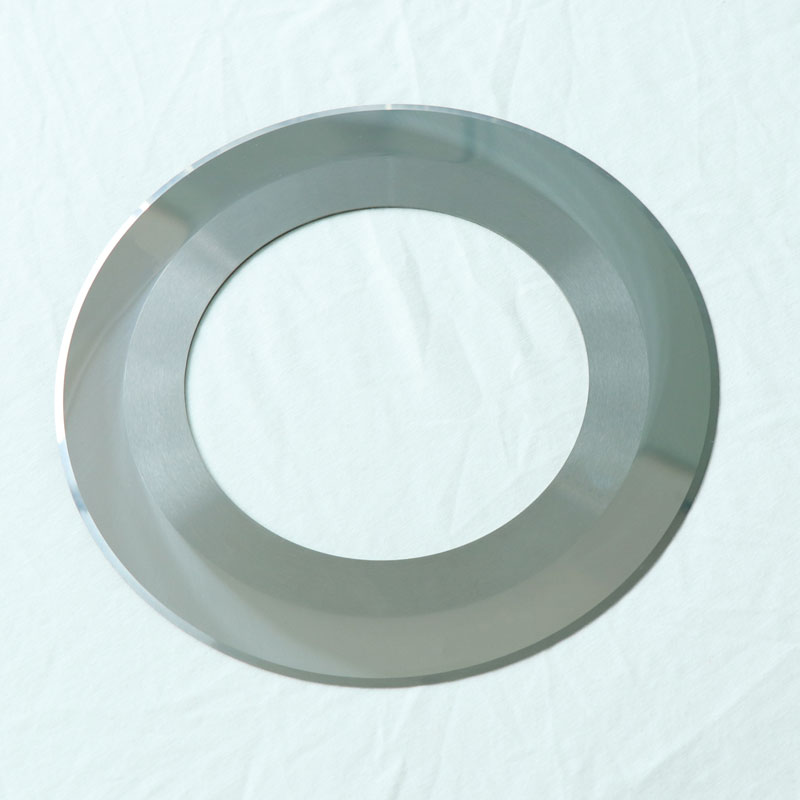

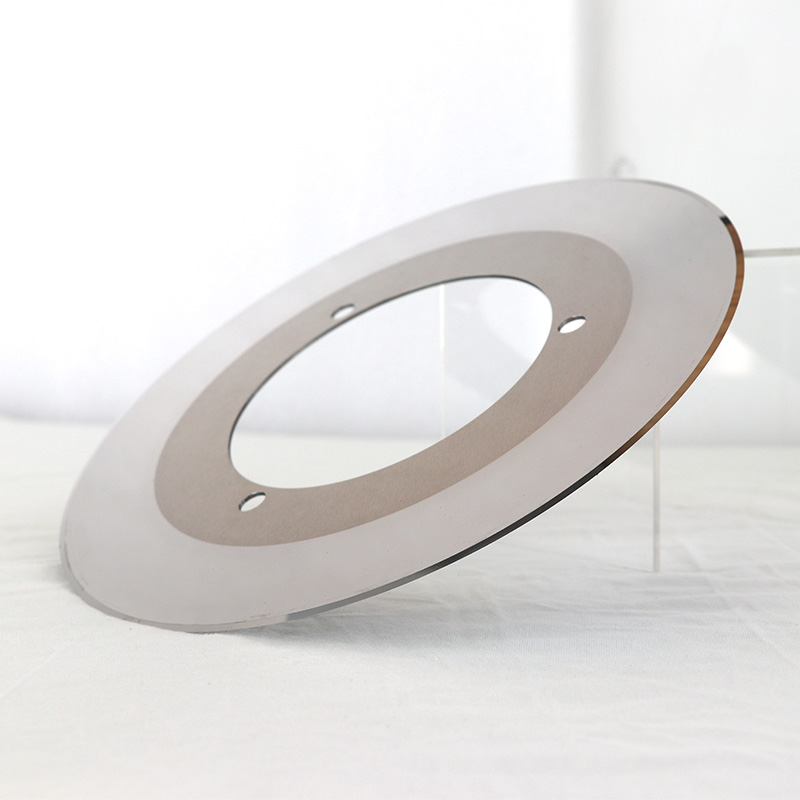

Our product Manufactured from the best quality steel to maximise cutting performance. The products we particularly recommend are 18% Tungsten Inlaid knives, Tungsten carbide Ultra Grain inlay is very stable and guarantees a keen edge and longevity when used in conditions absent of foreign bodies. With carbide there is less machine downtime and increased productivity making it ideal for heavy production runs. Ultra Grain outperforms standard carbide knives.

Specifications

| Product Name | Indexable knives | Surface | Mirror Polishing |

| Material | Tungsten Carbide | MOQ | 10 |

| Application | Solid Wood, MDF HDF Surface Planning | Logo | Accept Customized Logo |

| Hardness | 91-93HRA | Customized Support | OEM, ODM |

Specification

|

Common Size of Paper Cutting Knives (Polar) |

||||

|

Machine Models |

Length |

Width |

Thickness |

Holes |

|

Polar 55 |

685 |

95 |

9.7 |

14-M10 |

|

Polar 58 |

715 |

95 |

9.7 |

12-M10 |

|

Polar 71/72 |

868 |

104 |

9.7 |

12-M10 |

|

Polar 76 |

925 |

110 |

9.7 |

14-M10 |

|

Polar 78 |

960 |

107 |

9.7 |

6-M10 |

|

Polar 80 |

990 |

107 |

9.7 |

10-M10 |

|

Polar 82 |

990 |

107 |

11.7 |

10-M10 |

|

Polar 90 |

1080 |

115 |

11.7 |

11-M10 |

|

Polar 92 |

1095 |

115 |

11.7 |

11-M10 |

|

Polar 105 |

1325/1295 |

120 |

11.95 |

22-M10 |

|

Polar 115/115x |

1390 |

160 |

13.75 |

26/39-M12 |

|

Polar 137 |

1605 |

160 |

13.75 |

30-M12 |

|

Polar 155 |

1785 |

160 |

13.75 |

32-M12 |

How to choosing a correct knife angle?

In the operation of modern high-speed cutters it is unavoidable that cutting differences are encountered occasionally, in spite of accurate machine adjustment and most careful alignment of the material to be cut by the operator. The reason is to be found in the varying characteristics of the material to be cut. It would, therefore, be ideal if only one particular material were processed on one particular machine. Different materials require different knife angles and it is difficult to determine the correct knife angle if all sorts of material are to be cut successively at short intervals of time. In such cases a mean knife angle of 24° is recommended. If the customer does not explicitly order another knife angle the Polar HSS knives are delivered with an angle of 24°. This also applies to the standard equipment of new POLAR high speed cutters. The correct cutting angle and suitable knife determine to a large extent the cutting quality and economical operation of the high-speed cutter.

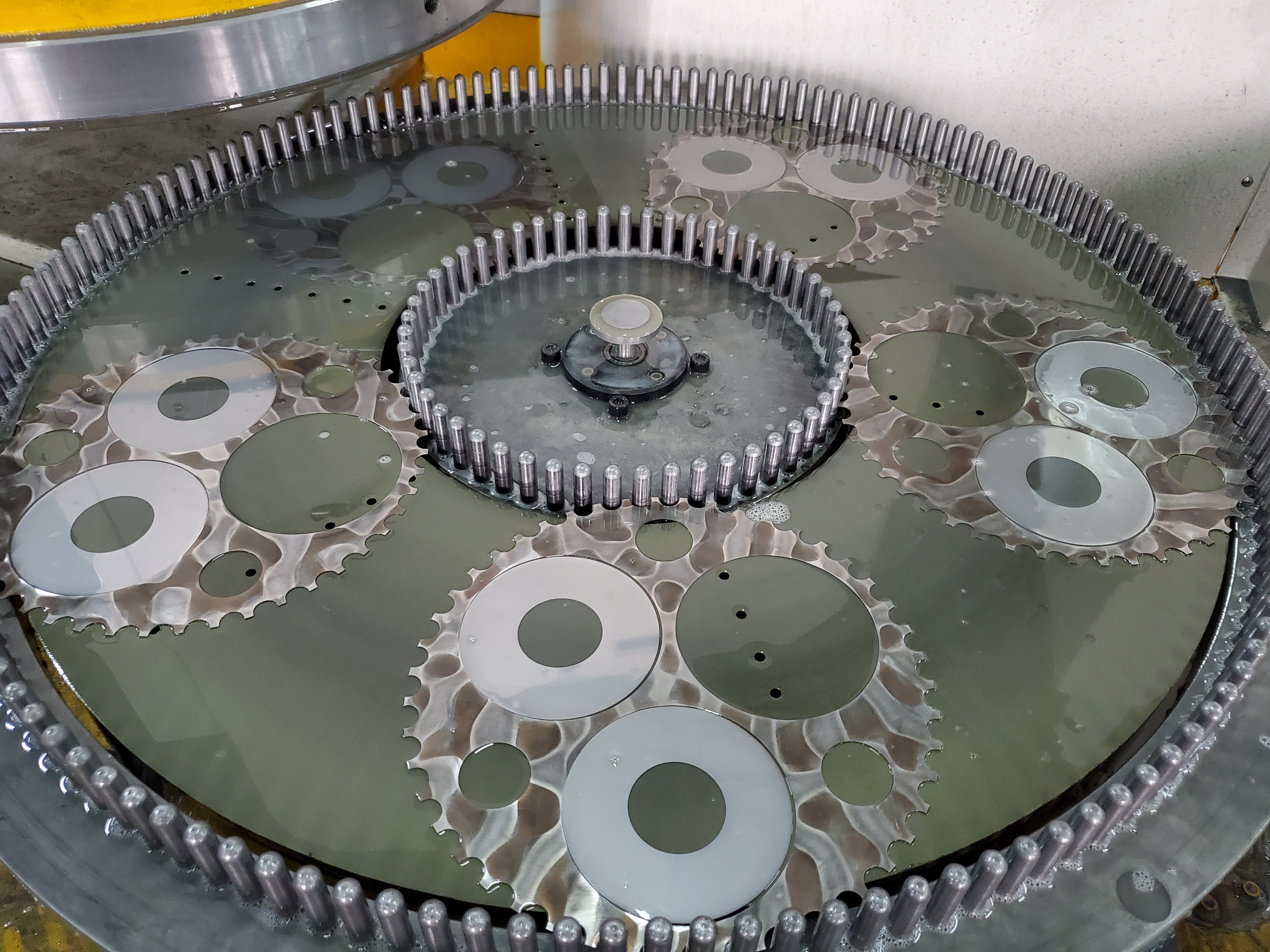

About Factory

Chengdu Passion is a comprehensive enterprise specialized in designing, manufacturing and selling all kinds of industrial and mechanical blades, knives and cutting tools for over twenty years. The factory is located in panda’s hometown Chengdu City, Sichuan Province.

The factory occupies almost three thousand square meters and includes over one hundred and fifty stuff. “Passion” has experienced engineers, quality department and completed production system, which includes press , heat treatment, milling, grinding and polishing workshops.

“Passion” supplies all kinds of circular knives, disk blades, knives of steel inlaid carbide rings, re-winder bottom slitter, long knives welded tungsten carbide, tungsten carbide inserts, straight saw blades, circular saw knives, wood carving blades and branded small sharp blades. Meanwhile, the customized product is available.