NC cut-off blades corrugated paperboard Cross cut blades

Product Introduction

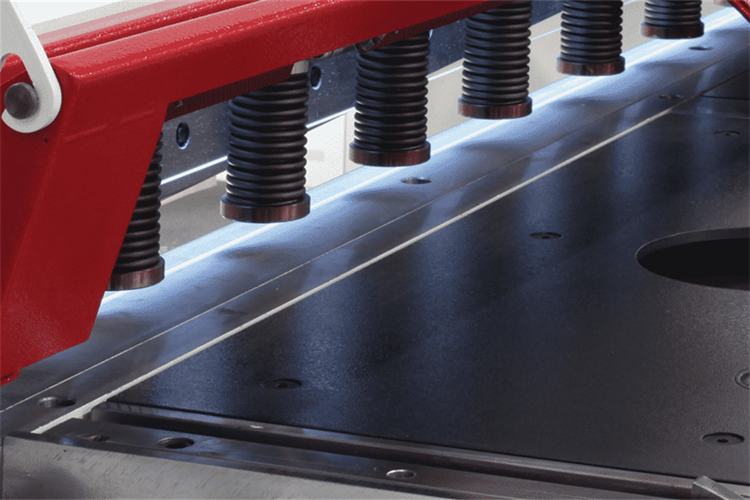

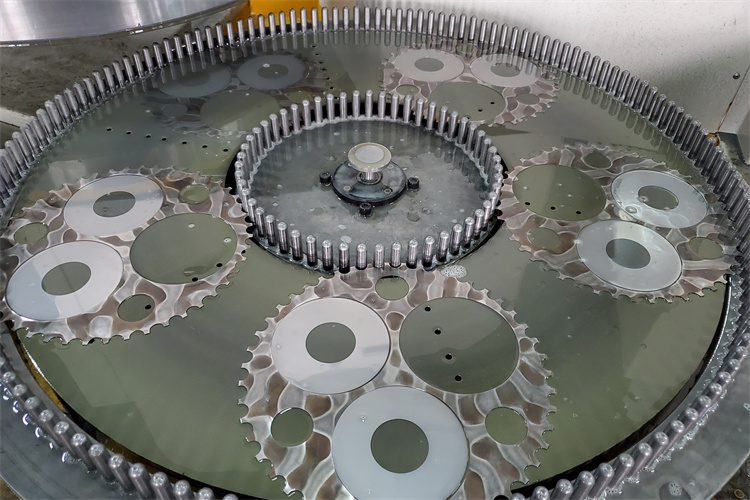

The shearing process is performed on a shear machine, that can be operated manually (by hand or foot) or by hydraulic, pneumatic, or electric power. A typical shear machine includes a table with support arms to hold the sheet, stops or guides to secure the sheet, upper and lower straight-edge blades, and a gauging device to precisely position the sheet. The sheet is placed between the upper and lower blade, which are then forced together against the sheet, cutting the material. In most devices, the lower blade remains stationary while the upper blade is forced downward. The upper blade is slightly off set from the lower blade, approximately 5-10% of the sheet thickness. Also, the upper blade is usually angled so that the cut progresses from one end to the other, thus reducing the required force. The blades used in these machines typically have a square edge rather than a knife edge and are available in different materials.There are several types of shearing tools and machines including Guillotine Machines. It’s a more complex shearing machine that’s powered either mechanically or hydraulically.

Product application

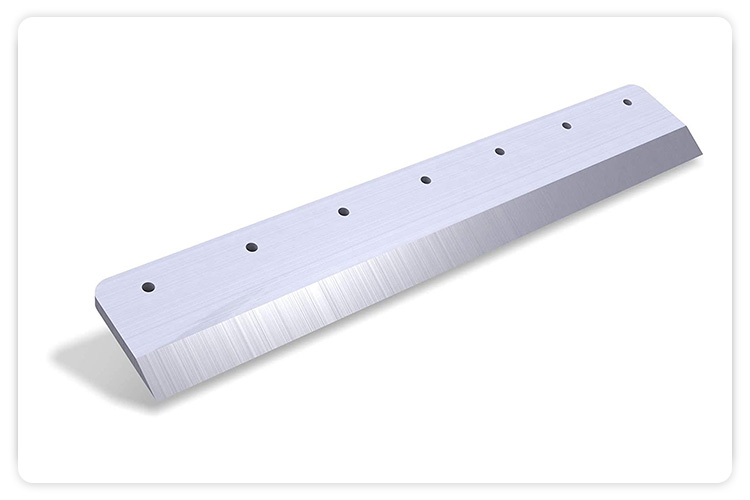

Our paper sheet shear blades are mainly used for sheet converting. Such as corrugated paperboard converting, paperboard converting. As for the NC cut-off blades. The assemble way similar as paper cutting guillotine blades. Shearing is performed by slicing through sheet metal with a blade-affixed machine or tool. Sheet metal is first secured between the tool’s or machine’s blades. Most shearing tools and machines have a squaring arm to control the location of the cut. After placing the sheet metal in the proper position with the squaring arm, the top blade drops to slice through the sheet metal. As the top blade comes down, the bottom of the sheet metal is pressed into a lower blade.

Product description

| Product Nume | Guillotine Blades |

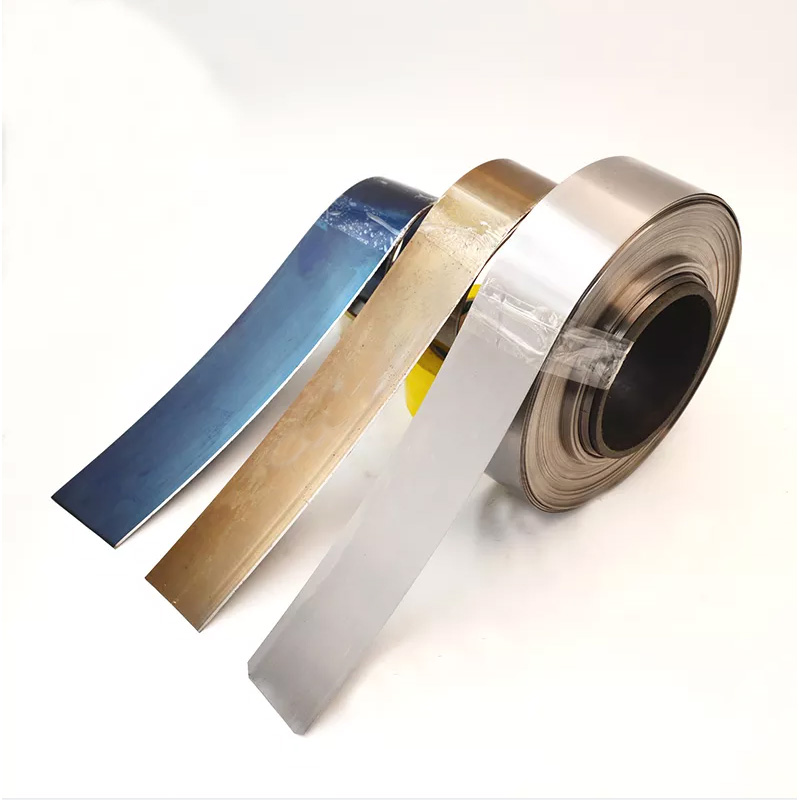

| Material | HSS W6, ASP, T1G, TC |

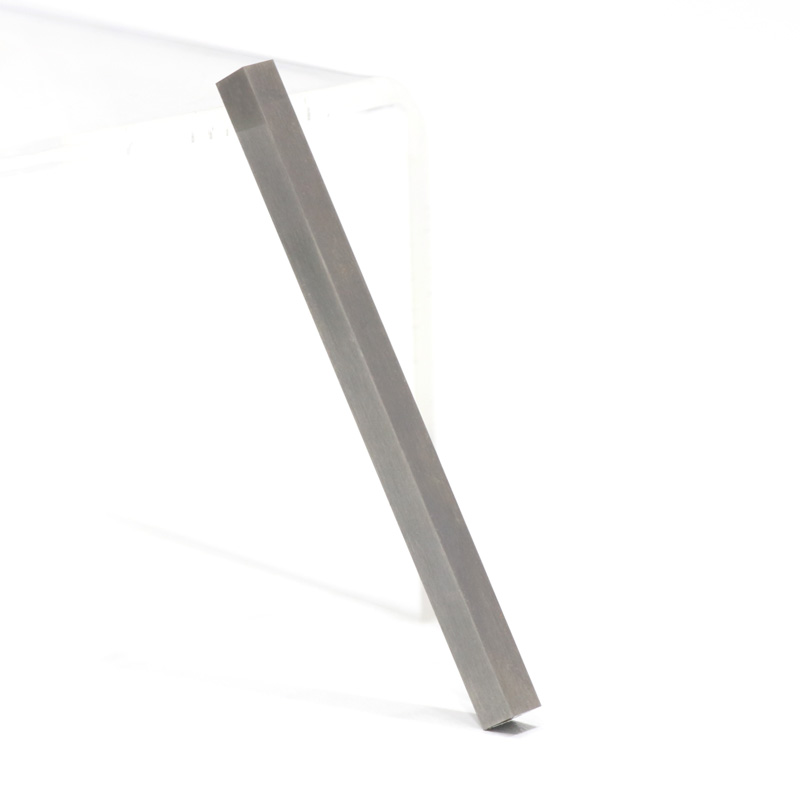

| Specifacation | Customized |

| Application | Paper, corrugated industry |

| Type | Top knife and bottom knife |

| Packing | Wooden Box, paper tube |

| Straightness | As client’s request |

introduction of the factory

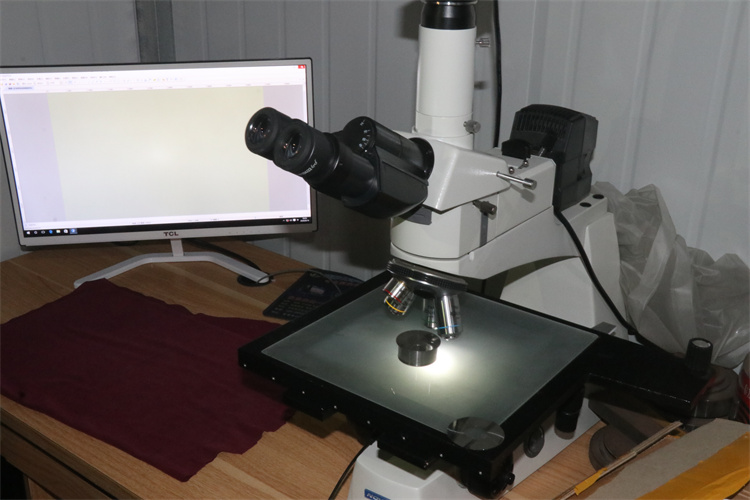

Chengdu PASSION precision tools Co., Ltd committed to providing customers with the best solutions according to their different requirements. We can design blades according to customer's purpose, including cutting edge, drawings and other details. And try our best to provide customers with the best solution. We can also customize blades for customers according to customer drawings and details of blades, and follow up with customers to select the most suitable materials to manufacture products for customers.We choose the highest quality Tungsten carbide raw material to make this knife, which ensures its durability for a certain period of time, which enables our customer to improve the production time. The risk of downtime is greatly reduced and the time cost is greatly saved. We designed the marking line on the surface of the knife for the customer, which is convenient for the customer to install the machine.

Packaging Details

Type 1: The blades are packed in suitable wooden cases and protected by foam inside.

Type 2: The blade is packed in a suitable cylindrical paper tube, and the inside is protected by foam to reduce the weight of the blade.