In the fast-paced world of manufacturing, the right tools make all the difference. As a professional tool manufacturer with 15 years of expertise, we specialize in navigating the complexities of slitting blades. Whether you're a business owner, purchasing manager, tool dealer, or a direct user in a large group, understanding how to select the appropriate slitting blades for different production processes is key to optimizing efficiency, quality, and cost-effectiveness.

For short runs, opt for carbon or stainless steel blades to manage costs without sacrificing quality. For longer production demands, high-grade materials like tungsten carbide are essential, reducing downtime and enhancing durability.

Choosing the appropriate blade material is not just about immediate needs but also about long-term efficiency and precision in every cut. Here’s how you can make an informed decision:

Understanding the Slitting Process

Slitting is a critical metal manufacturing process where a coil of material is slit into specified lengths and widths. It's a process that demands precision and reliability, making the choice of blade material pivotal.

Selecting Blade Materials

Blades are crafted from various materials, each suited to different tasks. For instance, carbon steel and stainless steel are cost-effective for short runs. However, for more demanding, longer runs, tungsten carbide stands out for its durability and minimal downtime.

Optimizing for Production Runs

Your production's scale significantly influences the choice of slitting blade material. Understanding the nuances between short and long production runs can guide you to the most suitable blade, balancing cost and performance efficiently.

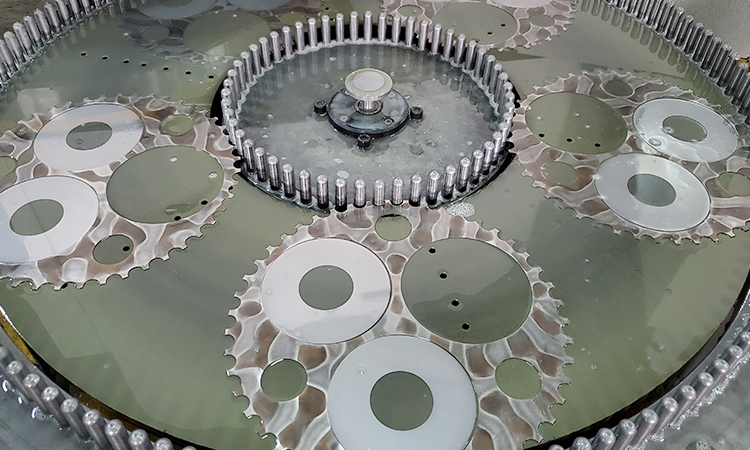

Manufacturing of Slitter Blades

The manufacturing process of slitter blades involves precise cutting, shaping, and finishing to ensure every blade meets the highest standards of quality and performance. Our commitment to excellence in manufacturing is evident in every blade we produce.

With over 15 years of experience, we pride ourselves on our ability to solve problems and offer professional advice on the best slitting blade for your needs. Trusting in expertise and precision engineering is paramount in making the right choice for your production process.Choosing the right slitting blades is a commitment to quality and efficiency. With the right expertise and tools, you can ensure that your manufacturing process runs smoothly, with precision in every cut. Rely on professional guidance and high-quality blades to meet your production needs effectively.

Post time: Mar-01-2024