In the previous article, we introduced the different types of industrial blades in tobacco manufacturing and the factors that should be considered when choosing an industrial cigarette knife, and today we continue to explain how to choose the size and shape of the cigarette knife and how to choose the appropriate blade.

Understanding the Importance of Blade Material in Tobacco Making

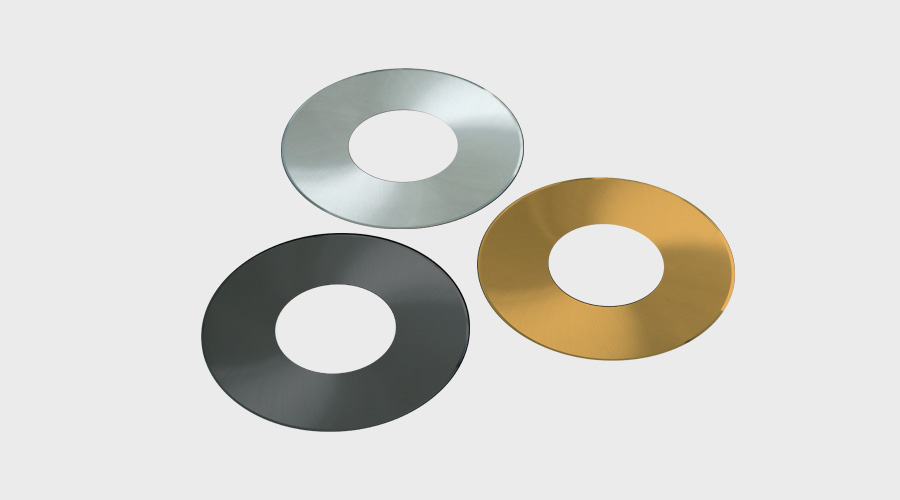

The material used in manufacturing industry blades for tobacco making significantly influences their performance and longevity. Common materials include high-carbon steel, stainless steel, and tungsten carbide, each offering unique advantages in terms of sharpness, durability, and resistance to corrosion. High-carbon steel blades are known for their sharp cutting edge and affordability, while stainless steel blades excel in corrosion resistance. Tungsten carbide blades are highly durable and maintain their sharpness over extended periods, making them ideal for heavy-duty cutting applications in tobacco manufacturing.

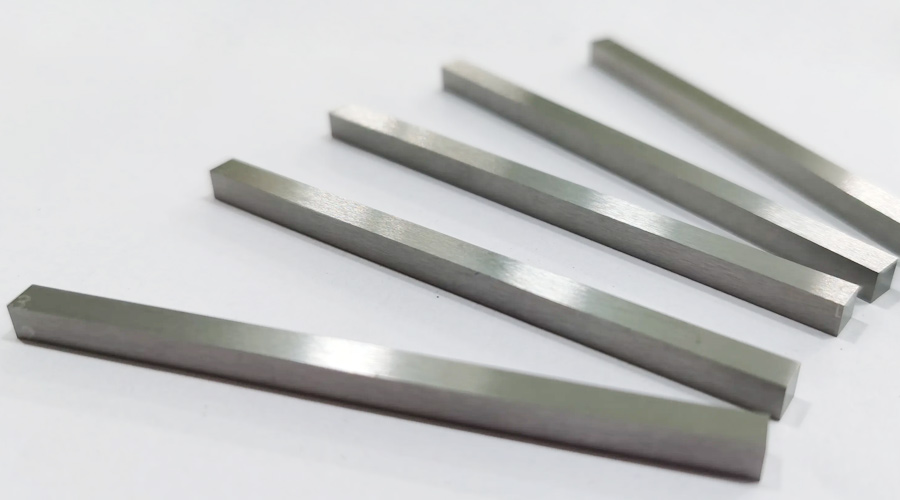

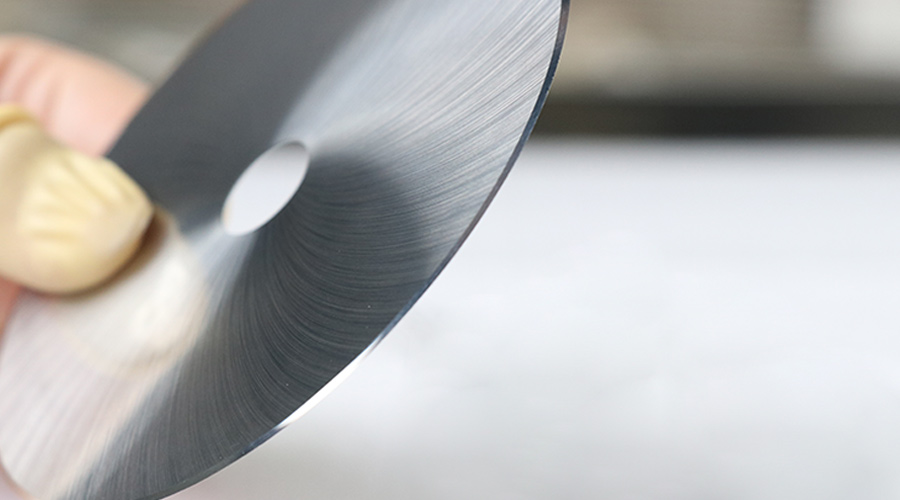

Blade Size and Shape Considerations for Tobacco Making

In tobacco making, the size and shape of industry blades are crucial factors that directly impact the precision and efficiency of the cutting process. Some common knife sizes are 100*15*0.2 mm round blade, 4*4 mm square blade, and 420*100*1.5 mm thin blade. The blade size should be chosen based on the specific requirements of the production line, ensuring that it can effectively handle the volume and thickness of tobacco materials being processed. Additionally, the blade shape plays a key role in determining the cutting pattern and speed, with options ranging from straight-edged blades for clean cuts to curved blades for intricate shaping tasks.

Choosing the Right Blade Edge for Tobacco Cutting

The choice of blade edge is another important consideration when selecting industry blades for tobacco cutting. Different types of blade edges, such as straight, serrated, or scalloped, offer distinct advantages depending on the desired cutting outcome. Straight edges are ideal for clean and precise cuts on softer tobacco leaves, while serrated edges provide enhanced grip and cutting power for tougher materials. Scalloped edges offer a combination of slicing and tearing capabilities, making them suitable for a variety of cutting tasks in tobacco manufacturing.

That's all for this article. If you need this tobacco blade or have some questions about it, you can contact us directly.

Later, We will continue to update information, and you can find more information on our website (passiontool.com) blog.

Of course, you can also pay attention to our Official social media:

Post time: Aug-09-2024