In the last article we learned what CNC technology is and the different types and functions of CNC knife blades. Today, we continue to explain the application of CNC knife blades in various industries, the factors that should be considered when choosing CNC knife blades and the advantages of CNC knife blades.

Applications of CNC Knife Blades in Various Industries

The versatility and precision of CNC knife blades make them indispensable tools in a wide range of industries, where cutting, shaping, and carving are essential processes. In the woodworking industry, CNC knife blades are used for precise cutting of wood materials to create custom furniture, cabinetry, and decorative elements. The ability to achieve intricate designs and smooth finishes makes CNC knife blades popular among woodworkers seeking high-quality craftsmanship and precision.

In the signage and graphics industry, CNC knife blades play a crucial role in cutting vinyl, foam board, and other materials used for signage production. The ability to cut precise letters, shapes, and logos with clean edges and smooth surfaces makes CNC knife blades ideal for creating professional signage and displays. The speed and accuracy of CNC machines equipped with knife blades enable sign makers to produce high-quality products quickly and efficiently.

In the automotive and aerospace industries, CNC knife blades are used for cutting gaskets, seals, and composite materials with precision and consistency. The ability to achieve tight tolerances and intricate shapes is essential in these sectors, where high-performance materials and complex designs are common. CNC knife blades provide the accuracy and reliability needed to meet the stringent requirements of automotive and aerospace applications, ensuring quality and reliability in the finished products.

Factors to Consider When Choosing a CNC Knife Blad

When selecting a CNC knife blade for a specific application, several factors must be taken into account to ensure optimal performance and efficiency. One of the key considerations is the material being cut, as different materials require specific blade types and cutting parameters to achieve clean and accurate cuts. Harder materials like metals may require carbide or diamond-coated blades for effective cutting, while softer materials like wood can be cut efficiently with high-speed steel (HSS) blades.

Another crucial factor to consider is the cutting speed and feed rate, which determine the rate at which the blade moves through the material. Adjusting these parameters according to the material properties and blade type is essential for achieving smooth and precise cuts without causing damage to the material or the blade. Additionally, the blade geometry and edge design play a significant role in the cutting performance, influencing factors such as chip evacuation, cutting forces, and surface finish.

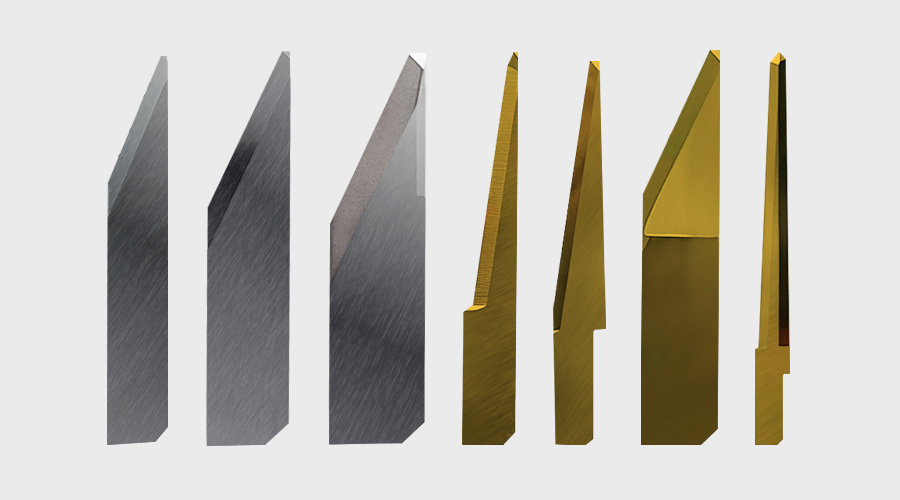

The overall design and construction of the CNC knife blade also impact its performance and longevity. Factors such as blade thickness, blade angle, and blade material quality can affect the blade's durability and cutting efficiency. Choosing a blade with the right combination of these factors is essential for maximizing productivity and achieving consistent cutting results. By carefully evaluating these factors and selecting a CNC knife blade that aligns with the specific requirements of the project, manufacturers can optimize their cutting processes and enhance overall production quality.

Advantages of Using CNC Knife Blades

The use of CNC knife blades offers numerous advantages in manufacturing processes, making them indispensable tools for precision cutting and shaping tasks. One of the key benefits of CNC knife blades is their ability to deliver consistent and accurate cuts, ensuring uniformity and quality in the finished products. The precise control provided by CNC machines allows manufacturers to achieve intricate designs and complex shapes with ease, enhancing the overall aesthetics and functionality of the final products.

Another advantage of using CNC knife blades is the efficiency and productivity they bring to production operations. By automating cutting tasks and eliminating manual errors, CNC machines equipped with knife blades can significantly reduce production time and costs while increasing output volumes. The high cutting speeds and precision of CNC knife blades enable manufacturers to streamline their processes and meet tight production deadlines without compromising on quality.

Furthermore, CNC knife blades offer versatility in cutting a wide range of materials, from softwoods and plastics to metals and composites. This versatility allows manufacturers to handle diverse projects and materials with a single tool, minimizing the need for multiple cutting implements and simplifying production workflows. Whether cutting intricate patterns in acrylic or trimming metal components with precision, CNC knife blades provide the flexibility and adaptability needed to tackle various cutting challenges effectively.

That's all for this article. If you need this CNC knife blades or have some questions about it, you can contact us directly.

Later, We will continue to update information, and you can find more information on our website (passiontool.com) blog.

Of course, you can also pay attention to our Official social media:

Post time: Aug-28-2024