In the last article we learned the application of CNC knife blades in various industries, the factors that should be considered when choosing CNC knife blades and the advantages of CNC knife blades. Today, we continue to explain how to maintain and care for CNC knife blades and how to buy high quality CNC blades.

How to Maintain and Care for CNC Knife Blades

Proper maintenance and care are essential for prolonging the life and performance of CNC knife blades, ensuring consistent cutting quality and efficiency. One of the key maintenance tasks is keeping the blade clean and free from debris, as buildup can affect cutting performance and lead to premature wear. Regularly inspecting the blade for signs of damage, such as chips or dull edges, is crucial for identifying issues early and preventing more significant problems.

Another important aspect of blade maintenance is sharpening and regrinding the blade as needed to maintain its cutting edge and effectiveness. Using the correct sharpening equipment and techniques is essential for preserving the blade's geometry and ensuring optimal cutting performance. Additionally, lubricating the blade and adjusting cutting parameters according to the material properties can help prolong the blade's life and maintain cutting precision.

Proper storage of CNC knife blades is also critical for preventing damage and preserving their sharpness. Storing blades in a clean, dry environment away from moisture and contaminants can help extend their lifespan and maintain their cutting quality. It is advisable to use protective covers or cases to shield the blades from dust and other particles that could impact their performance. By following these maintenance practices and caring for CNC knife blades diligently, manufacturers can maximize the longevity and efficiency of their cutting tools.

Where to Buy High-Quality CNC Knife Blades

When looking to purchase high-quality CNC knife blades for your manufacturing needs, it is essential to source them from reputable suppliers and manufacturers known for their precision and reliability. Many specialized companies offer a wide selection of CNC knife blades tailored to different cutting applications and materials, ensuring that you find the right tool for your specific requirements. These suppliers often provide detailed product information, including blade specifications, materials, and compatibility, to help you make informed purchasing decisions.

Online marketplaces and industrial supply stores are common sources for purchasing CNC knife blades, offering a convenient platform to browse and compare various blade options from different manufacturers. Additionally, reaching out to CNC machine manufacturers or distributors can provide valuable insights and recommendations on the best blade types for your specific machine model and cutting needs. By consulting with industry experts and exploring different suppliers, you can find high-quality CNC knife blades that meet your performance expectations and production requirements.

Before making a purchase, it is advisable to review customer reviews and testimonials to gauge the quality and reliability of the CNC knife blades offered by different suppliers. Feedback from other users can provide valuable insights into the performance and durability of the blades, helping you make an informed decision. Additionally, consider factors such as pricing, warranty options, and customer support services when selecting a supplier to ensure a seamless purchasing experience and satisfaction with your CNC knife blade investment.

If you have needs, you can also contact us. We also produce a variety of high quality CNC knife blades. Or you have any questions or want to get help, we can also answer for you.

Conclusion: Choosing the Right CNC Knife Blade for Your Needs

In conclusion, CNC knife blades are indispensable tools for precision cutting and shaping tasks in various industries, offering unparalleled control and efficiency in material processing. By understanding the different types of CNC knife blades, factors to consider when choosing a blade, advantages of using these blades, applications across industries, maintenance practices, and where to purchase high-quality blades, manufacturers can optimize their cutting processes and achieve superior results.

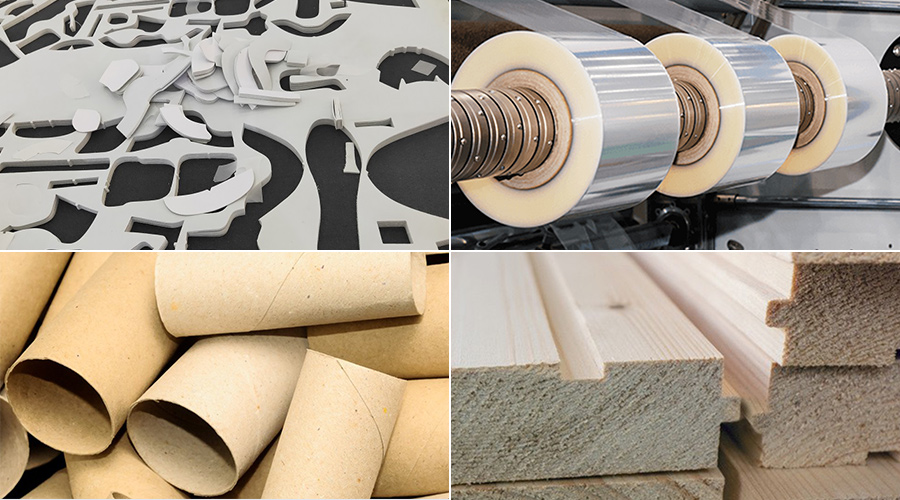

Selecting the right CNC knife blade for your specific needs involves evaluating factors such as material properties, cutting requirements, and blade design to ensure optimal performance and efficiency. By considering these factors and following proper maintenance practices, manufacturers can prolong the life of their CNC knife blades and maintain cutting quality over time. Whether cutting wood, plastics, metals, or composites, choosing the right CNC knife blade is essential for achieving precision and consistency in production operations.

In the ever-evolving manufacturing landscape, CNC technology and knife blades continue to drive innovation and efficiency, empowering manufacturers to push the boundaries of design and production capabilities. By harnessing the full potential of CNC knife blades and leveraging their versatility and precision, manufacturers can elevate their craft to new heights and deliver exceptional products that meet the demands of the modern market. With the right knowledge, tools, and expertise, mastering the art of CNC cutting with knife

That's all for this article. If you need this CNC knife blades or have some questions about it, you can contact us directly.

Later, We will continue to update information, and you can find more information on our website (passiontool.com) blog.

Of course, you can also pay attention to our Official social media:

Post time: Sep-06-2024