In the world of manufacturing and industrial machinery, the quality and efficiency of slitter blades can make all the difference. These small but mighty blades are essential for cutting a wide range of materials with precision and accuracy. However, finding the right slitter blades for each application can be a daunting task. That's where this ultimate guide comes in.

In this comprehensive guide, we will unlock the secrets of slitter blades, providing you with the knowledge you need to make informed decisions. From understanding the different types of blades available to learning about the key factors to consider when selecting the right blade for your needs, we leave no stone unturned. You'll also find valuable tips and insights from industry experts, ensuring that you have all the information required to unlock the cutting edge in your production process.

Whether you're a seasoned professional or just starting out, this guide is a must-read for anyone looking to optimize their slitting operations. So, let's dive in and discover the world of slitter blades together.

Types of Slitter Blades and Their Applications

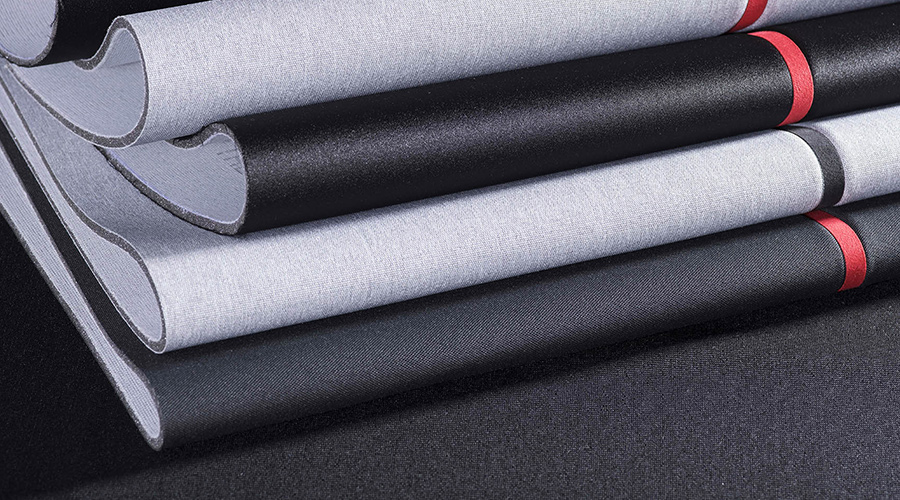

Slitter blades come in various types, each designed for specific cutting applications. Some common types include razor blades, shear blades, guillotine blade, crush cut blades, rotary slitter blades and dished slitter blades. Razor blades are ideal for precise and clean cuts on thin materials like paper and film, mainly used in the packaging and printing industry. Shear blades, on the other hand, are suitable for cutting thicker materials such as cardboard and rubber due to their strength and durability. Crush cut blades are used in industries such as foam and textile manufacturing to crush and cut materials like foam and textiles. In the textile industry, rotary slitter blades are often used to cut fabrics into desired widths efficiently. These blades provide a high level of precision and can handle multiple layers of fabric simultaneously. For industries dealing with films and foils, dished slitter blades are the go-to choice, as they can easily slice through these challenging materials without causing damage.

In addition to the common types mentioned, some specialized industries, such as medical device manufacturing, may require custom slitter blades tailored to their specific requirements, like circular slitter blades and dished slitter blades that meet the unique cutting challenges posed by intricate medical components. Circular slitter blades are perfect for continuous cutting processes, while dished slitter blades are designed to handle challenging materials like foils and laminates. Knowing the diverse range of slitter blade types available can help you select the most suitable one for your specific cutting tasks.

Understanding the differences between these types and their applications can help you choose the right one for your cutting needs. It's also worth noting that matching the type of slitter blade to the material and thickness you are working with, you can achieve optimal cutting results and improve overall efficiency in your production process.

Factors to Consider When Choosing Slitter Blades

Choosing the right slitter blades is essential for achieving optimal cutting performance and prolonging the lifespan of your equipment. Several factors should be taken into account when selecting slitter blades, including the type of material being cut, the desired cutting precision, and the speed of the cutting process. Additionally, factors such as blade material, blade geometry, and blade hardness can significantly impact the cutting results.

The type of material being cut plays a critical role in determining the blade type and edge geometry required for the job. For instance, materials like paper and film may require razor blades with a fine edge for clean cuts, while tougher materials like rubber and plastics may demand shear blades with a more robust cutting edge. Understanding the properties of the material being cut is crucial for choosing the right blade that can effectively slice through it without causing damage.

Another important factor to consider is the desired cutting precision. Different cutting applications may require varying levels of accuracy, ranging from standard cuts to intricate patterns. Selecting slitter blades with the appropriate blade geometry, such as blade thickness and angle, can help achieve the desired cutting precision. Additionally, the speed of the cutting process should be considered, as faster cutting speeds may necessitate blades with enhanced durability and wear resistance to maintain cutting performance over time.

That's all for today, if you are interested in this, please feel free to contact us and we will update the next post as soon as possible.

Later, We will continue to update information, and you can find more information on our website (passiontool.com) blog.

Of course, you can also pay attention to our Official social media:

Post time: Jul-11-2024