In The last article, we talked about the types and application scenarios of slitter knives and the factors that should be considered when choosing slitter blades. Today, we will continue with the second part of The Ultimate Guide to Slitter Blades.

The Importance of Sharpness in Slitter Blades

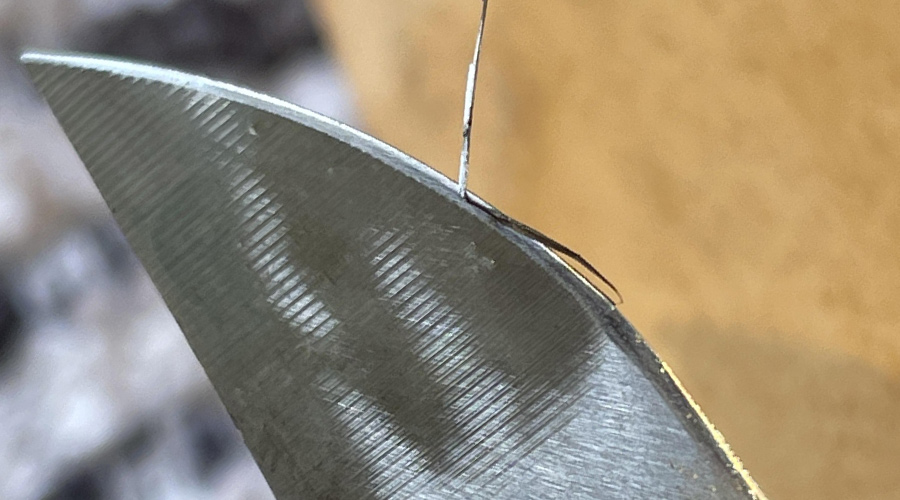

Sharpness is a key factor that significantly impacts the cutting performance of slitter blades. A sharp blade ensures clean and precise cuts, reduces material waste, and enhances overall cutting efficiency. Dull blades, on the other hand, can lead to jagged edges, tearing of materials, and decreased productivity. Maintaining the sharpness of slitter blades is essential for achieving high-quality cutting results and prolonging the lifespan of the blades.

Regular blade sharpening and maintenance are crucial to keep slitter blades in optimal condition. Depending on the cutting frequency and material type, blades may need to be sharpened periodically to maintain their sharp edge. Using proper sharpening techniques and tools, such as sharpening stones or grinding machines, can help restore the sharpness of dull blades and ensure consistent cutting performance. Additionally, proper storage and handling of blades can help prevent damage and maintain sharpness over time.

In addition to sharpening, proper blade alignment and setup are essential for maximizing cutting precision and sharpness. Misaligned blades can cause uneven cutting, leading to jagged edges and material distortion. Regularly inspecting and adjusting blade alignment can help ensure that the blades are positioned correctly for optimal cutting performance. By prioritizing sharpness and implementing effective maintenance practices, you can enhance the cutting efficiency and longevity of your slitter blades.

Best Practices for Maximizing the Lifespan of Slitter Blades is Maintenance and Care

To maximize the lifespan of slitter blades and ensure consistent cutting performance, it is important to follow best practices for blade maintenance and care. One key practice is to regularly inspect blades for signs of wear and damage, such as nicks, chips, or dull spots. Addressing any issues promptly through blade sharpening or replacement can help prevent further damage and maintain cutting precision.

Proper storage of blades is also essential for prolonging their lifespan. Storing blades in a clean and dry environment, away from moisture and contaminants, can help prevent corrosion and maintain blade sharpness. Using protective covers or sheaths when storing blades can further protect them from damage and ensure they remain in optimal condition.

In addition to regular maintenance, implementing a preventive maintenance schedule can help extend the lifespan of slitter blades and prevent unexpected downtime. By establishing a routine maintenance plan that includes blade sharpening, cleaning, and lubrication, you can ensure that the blades remain in top condition and deliver consistent cutting results. Following these best practices can help maximize the lifespan of slitter blades and optimize cutting efficiency in your production process.

Common Problems and Troubleshooting for Slitter Blades

Despite proper maintenance, slitter blades may encounter common issues that can affect cutting performance. Some common problems include blade dullness, edge chipping, and blade misalignment. Dull blades can result in poor cutting quality and increased material waste, while edge chipping can lead to uneven cuts and jagged edges. Blade misalignment can cause cutting inaccuracies and material distortion.

To troubleshoot these issues, it is essential to identify the root cause of the problem. Dull blades may require sharpening or replacement, depending on the extent of wear. Edge chipping can be addressed by inspecting the blade for damage and adjusting cutting parameters if necessary. Blade misalignment may be corrected by realigning the blades and ensuring proper setup for optimal cutting performance.

In some cases, upgrading to higher-quality blades or adjusting cutting parameters, such as blade speed and pressure, can help resolve common cutting problems. Regularly monitoring blade performance and addressing issues promptly can help prevent downtime and maintain efficient cutting operations. By understanding common problems and implementing effective troubleshooting techniques, you can optimize the performance of your slitter blades and improve overall cutting quality.

This is the end of today's content, if you are interested, or have slitter blades need, feel free to contact us.

Later, We will continue to update information, and you can find more information on our website (passiontool.com) blog.

Of course, you can also pay attention to our Official social media:

Facebook(https://www.facebook.com/passionknife)

Pinterest(https://www.pinterest.com/passiontool/)

Instagram(https://www.instagram.com/px13882246828/)

Post time: Jul-19-2024