In the previous article, we talked about the importance of Slitter Blades sharpness, and how the best practice to maximize the service life of Slitter Blades is to maintain and maintain the innovation and advancement of Slitter Blades technology. Today, we will continue the third and final part of the final guide to slitter machine blades.

Innovations and Advancements in Slitter Blade Technology

Advancements in slitter blade technology have led to the development of innovative cutting solutions that offer improved performance and efficiency. One notable innovation is the use of carbide-tipped blades, which provide enhanced durability and wear resistance compared to traditional steel blades. Carbide-tipped blades are ideal for cutting abrasive materials and can maintain sharpness over a longer period, reducing the frequency of blade sharpening.

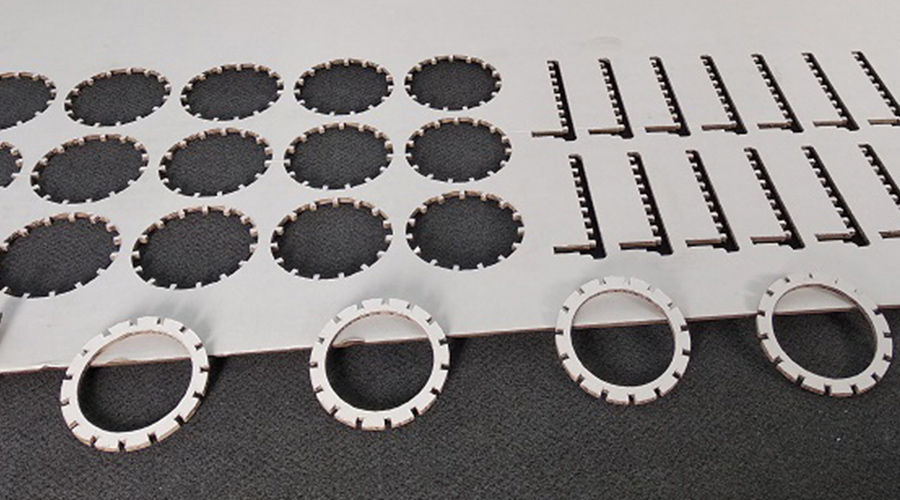

Another technological advancement is the integration of laser cutting technology in slitter blades, enabling precision cutting of intricate patterns and shapes. Laser-cut blades offer high cutting accuracy and clean edges, making them suitable for industries that require high-precision cutting, such as electronics and medical device manufacturing. The use of laser technology also allows for faster cutting speeds and reduced material waste.

In addition to material and cutting technology advancements, innovations in blade design and manufacturing processes have contributed to the development of slitter blades with improved performance characteristics. Blades with specialized coatings, such as diamond-like carbon (DLC) coatings, offer increased hardness and wear resistance, prolonging blade lifespan and reducing maintenance requirements. These advancements in slitter blade technology continue to push the boundaries of cutting efficiency and precision, enabling manufacturers to achieve higher productivity and quality in their cutting operations.

Selecting the Right Slitter Blades for Your Specific Needs

When selecting slitter blades for your specific cutting needs, it is important to consider factors such as the type of material being cut, the cutting precision required, and the speed of the cutting process. Different types of materials may demand specific blade types and edge geometries to achieve optimal cutting results. For instance, materials like paper and film may require razor blades for clean cuts, while tougher materials like rubber and plastics may necessitate shear blades for efficient cutting.

The desired cutting precision also plays a crucial role in selecting the right slitter blades. Depending on the level of accuracy needed for your cutting applications, you may opt for blades with specific blade geometries and edge angles that can deliver precise cuts consistently. Considering the speed of the cutting process is important as well, as faster cutting speeds may require blades with enhanced durability and wear resistance to maintain cutting performance over time.

In addition to material type, cutting precision, and speed, it is essential to evaluate other factors such as blade material, hardness, and coating when choosing slitter blades. Selecting blades made from high-quality materials and featuring appropriate hardness levels can improve cutting efficiency and longevity. Blades with specialized coatings, such as titanium nitride (TiN) coatings, offer increased wear resistance and can extend blade lifespan. By carefully assessing your specific cutting needs and considering these factors, you can select the right slitter blades that meet your requirements and optimize cutting performance.

Conclusion and Final Thoughts

In conclusion, slitter blades are essential cutting tools that play a critical role in various industries, from packaging to textiles. Understanding the different types of slitter blades available, their applications, and the factors to consider when choosing the right blade is crucial for achieving optimal cutting results and maximizing efficiency. By prioritizing sharpness, maintenance, and proper care, you can prolong the lifespan of slitter blades and ensure consistent cutting performance.

Innovations in slitter blade technology continue to drive advancements in cutting efficiency and precision, offering manufacturers new opportunities to enhance their cutting operations. By following best practices for blade maintenance and selecting the right slitter blades for your specific needs, you can optimize cutting efficiency, reduce material waste, and improve overall productivity in your production process.

In the ever-evolving world of manufacturing and industrial machinery, unlocking the cutting edge with the ultimate guide to slitter blades is key to staying ahead of the competition and achieving cutting perfection. With the knowledge and insights gained from this guide, you are equipped to make informed decisions and elevate your cutting operations to new heights. So, embrace the world of slitter blades, explore the possibilities they offer, and unlock the cutting edge in your production process.

If you need this blade or have some questions about it, you can contact us directly.

Later, We will continue to update information, and you can find more information on our website (passiontool.com) blog.

Of course, you can also pay attention to our Official social media:

Post time: Jul-26-2024