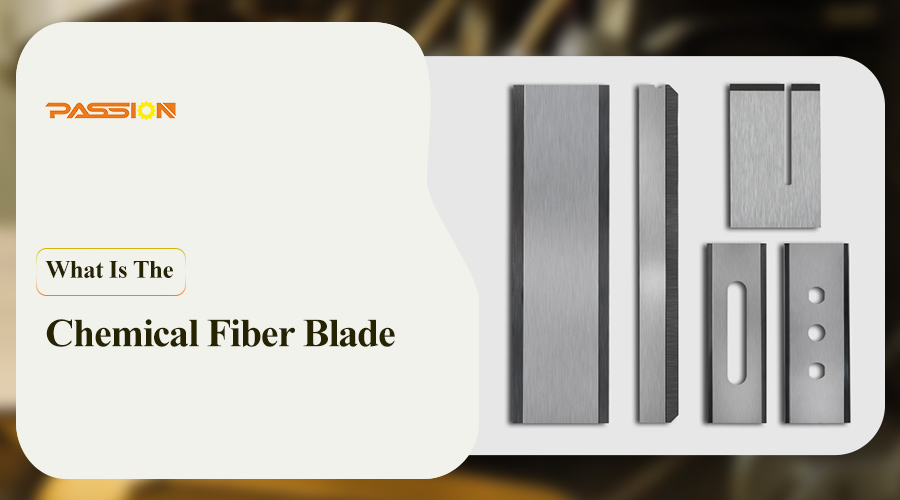

In the textile industry, Chemical Fibers have become an indispensable material due to their unique properties and wide range of applications. And chemical fiber blades as the processing and production of chemical fibers as a key tool, but also plays a pivotal role. This article will explore the role of chemical fiber blades, as well as its advantages and disadvantages in use.

Chemical fiber blades are mainly used in the cutting, carding and processing of chemical fibers. In the production line of chemical fibers, the blade ensures that the length, shape and uniformity of the fibers meet the process requirements through precise cutting. Meanwhile, in the carding process, the blades help fiber dispersion, straighten, and provide high-quality fiber raw materials for subsequent textile processing. It can be said that the chemical fiber blade is to ensure the quality of chemical fiber and textile product quality is a key link.

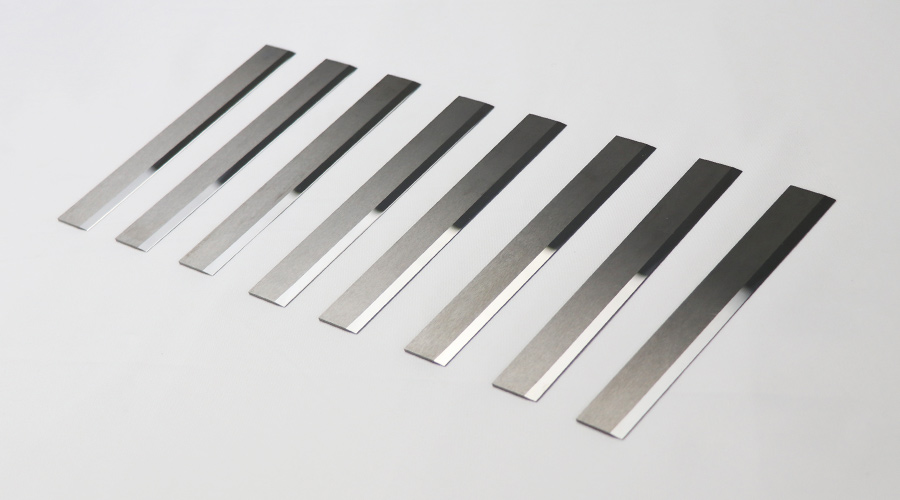

The use of chemical fiber blade has many advantages. First of all, its high cutting efficiency, can greatly improve production efficiency. Due to the texture and characteristics of chemical fibers, the traditional cutting method is often time-consuming and laborious, while the chemical fiber blade with its sharp edge and precise cutting effect, significantly improving the cutting speed. Secondly, chemical fiber blades have good wear resistance and durability. In the long-term cutting and carding process, the blade can maintain the sharpness of the edge, reducing the frequency of replacement, reducing production costs. In addition, the chemical fiber blade also has a high degree of precision and stability, can ensure the uniformity and consistency of fiber cutting, improve the quality of textile products.

However, chemical fiber blades also have some disadvantages. One of the main disadvantages of chemical fiber blades is that they are prone to wear and tear. Due to the constant friction and abrasion of the fibers during the cutting and carding process, the blades will gradually lose their sharpness and precision over time. This can lead to a reduction in cutting efficiency and an increase in the frequency of blade replacement, which can be costly and time-consuming. Another disadvantage is potential blade deformation or damage during use. Chemical fibers vary greatly in composition, texture, and density, which can place varying stresses on the blade. If the blades are not designed or manufactured to withstand these stresses, they may deform or become damaged, which can affect their cutting performance and shorten their service life.

In addition, the performance of chemical fiber blades is affected by a variety of factors. For example, the material, hardness, and edge angle of the blade all have an impact on its cutting effect and durability. Therefore, in the selection and use of chemical fiber blades, need to be based on specific process requirements and fiber characteristics for comprehensive consideration, in order to ensure that the performance of the blade is given full play.

In summary, chemical fiber blades play a vital role in the textile industry. Its efficient cutting performance, good wear resistance and durability, as well as high-precision cutting effect, provides strong support for the production of chemical fibers and processing of textile products. However, its relatively high manufacturing costs and wear problems during use also require our full attention and focus during use. In the future, with the continuous progress of technology and material innovation, we have reason to believe that the chemical fiber blade will be more excellent performance and a wider range of applications, for the development of the textile industry to inject new vitality.

Later, We will continue to update information, and you can find more information on our website (passiontool.com) blog.

Of course, you can also pay attention to our Official social media:

Post time: Jan-23-2025