The Arc-shape slotter blade plays a vital role in the corrugated industry. The unique design of this blade, with its rounded shape, gives it greater efficiency and precision in the slotting process, making it an important tool in the corrugated paper production line. This article will delve into the specific applications and roles of the Arc-shape slotter blade in the corrugated industry.

Corrugated board is a sheet made of hanging paper and wave-shaped corrugated paper bonded by corrugated roll processing. It has the advantages of low cost, light weight, easy processing and high strength, and is widely used as a packaging material for food products, digital products and other packaging materials. Grooving is an essential process in the production of corrugated board. The purpose of this process is to form a certain indentation in the cardboard, so that the corrugated cardboard can be bent accurately in a predetermined position to achieve the internal dimensions of the carton.

The Arc-shape slotter blade is the key tool for this process. With its unique arc shape, it can easily create one or more grooves in the corrugated board. These grooves not only make it easier to bend the cardboard, but also ensure that the structure of the carton is more stable, thus increasing its compression resistance and load carrying capacity.

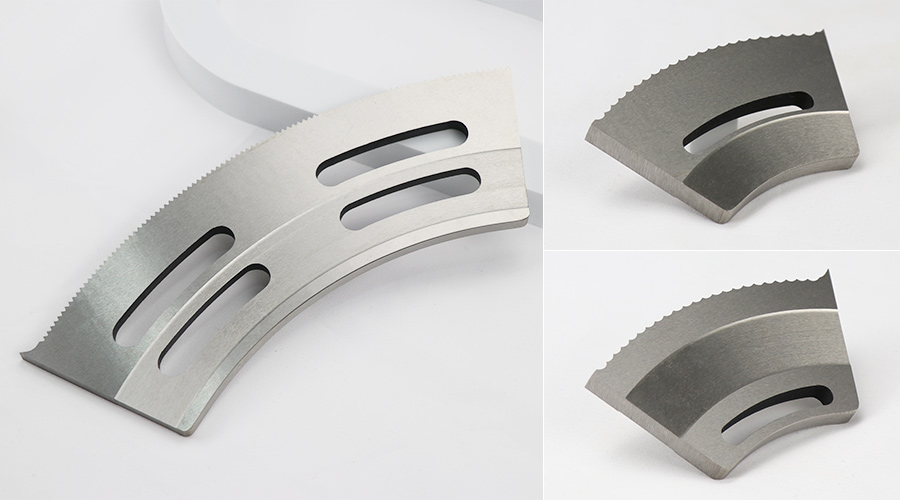

The choice of material for the Arc-shape slotter blade is also critical. Common blade materials include tungsten carbide (TC), high-speed steel (HSS), Cr12MoV (D2, also known as SKD11), and 9CrSi, each of which has its own advantages and disadvantages, but Cr12MoV and 9CrSi are the preferred materials for Arc-shape slotter blades in the corrugated industry because of their high hardness and wear resistance. These materials not only ensure blade durability, but also maintain stable cutting performance over long periods of time.

In practice, the Arc-shape slotter blade performs impressively. Thanks to its rounded shape, the blade distributes pressure more evenly during grooving, which reduces the breakage rate of cardboard. At the same time, the blade significantly improves line efficiency and reduces production costs.

In addition, the Arc-shape slotter blade has the advantage of being easy to replace and maintain. When the blade wears out, it can be easily replaced with a new one without the need for extensive dismantling and maintenance of the entire machine. This not only saves time, but also reduces maintenance costs.

As the corrugated industry continues to grow, so does the demand for Arc-shape slotter blades. To meet this demand, many companies are working to develop more efficient and durable blades. These new blades not only offer higher cutting accuracy and longer service life, but can also be adapted to the needs of different types of corrugated paper and carton production.

In summary, the Arc-shape slotter blade plays a pivotal role in the corrugated industry. Its unique arc shape design, high-quality material selection, and ease of replacement and maintenance make it an important tool in the corrugated paper production line. In the future, as the corrugated industry continues to develop and technology advances, the Arc-shape slotter blade's performance and range of applications will be further enhanced and expanded.

Later, We will continue to update information, and you can find more information on our website (passiontool.com) blog.

Of course, you can also pay attention to our Official social media:

Post time: Jan-10-2025