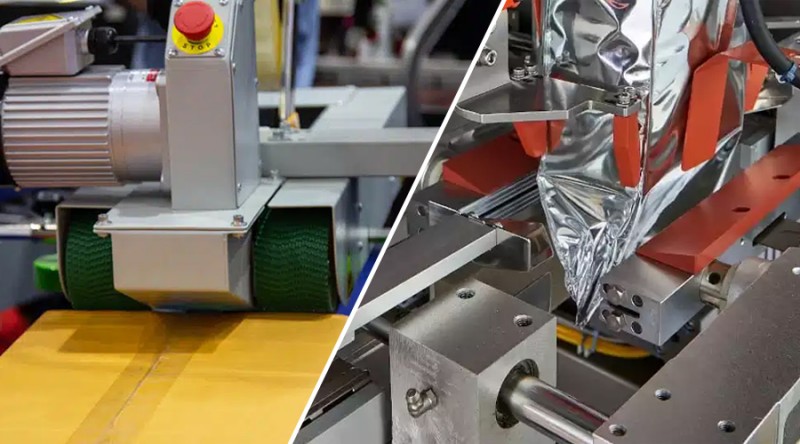

VFFS (Vertical Form Fill and Seal) and HFFS (Horizontal Form Fill and Seal) knives play a vital role in the food processing and packaging industry. Choosing the right tooling not only improves productivity, but also ensures product quality and safety. Below is the key information you need to know when purchasing VFFS and HFFS knives, especially the section on blade type and other important factors.

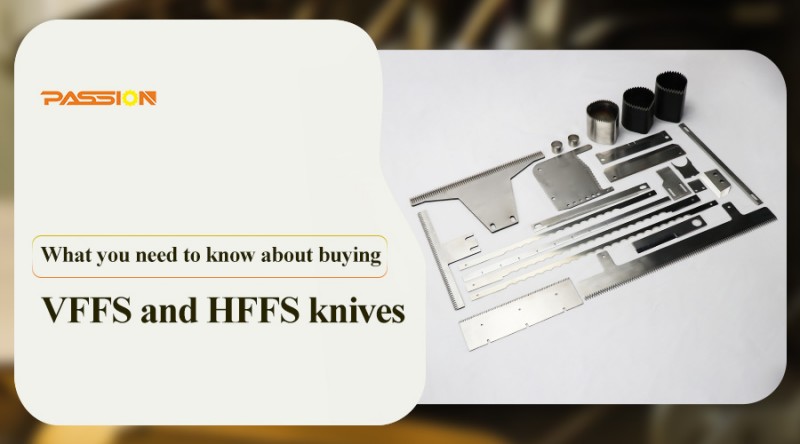

First of all, blade type is one of the key factors that determine the performance and life of a tool. Common blade types used in VFFS and HFFS applications include thermal transfer blades, flat ground blades and serrated blades. Thermal transfer blades are mainly used to print information on packaging materials and require good thermal conductivity and wear resistance; flat grinding blades are widely used in the cutting and sealing process to ensure that the cutting edges are smooth and burr-free; and serrated blades are mainly used in applications that require more cutting power, with higher strength and toughness.

In addition to blade type, there are several other important factors to consider when making a purchase. The first is the size of the blade. The size of the blade must match the cutting groove of the machine to ensure cutting accuracy and stability. If the blade size is too large or too small, it may result in inaccurate cutting or even damage to the machine. Therefore, when choosing a blade, make sure to double check the specifications and requirements of the machine to ensure that the blade size meets the requirements.

Next is the thickness of the blade. The thickness of the blade will directly affect the cutting strength and durability. Thicker blades usually have more cutting power and better durability, but they may also increase the load and wear on the machine. Therefore, when choosing blade thickness, you need to consider factors such as cutting needs, machine performance and cost to find the best balance.

In addition, the material of the blade is also a factor that should not be ignored. Blades made of different materials have different characteristics such as hardness, wear resistance and corrosion resistance. When choosing the material, it is necessary to make comprehensive consideration according to the type of packaging materials, the conditions of the working environment and the cutting requirements and other factors. For example, for the need to cut harder or thicker packaging materials, you can choose a higher hardness, wear resistance, better blade material; for frequent contact with corrosive substances, you need to choose more corrosion-resistant blade material.

In addition to the above factors, when buying also need to pay attention to the brand of the knife and the manufacturer's reputation. Knives of well-known brands usually have higher quality and more reliable after-sales service, which can provide stronger protection for your production. When choosing a brand and manufacturer, you can check relevant product reviews and user feedback to understand the performance and reputation of the product in order to make a more informed decision.

In conclusion, when purchasing VFFS and HFFS knives, you need to consider a number of factors such as blade type, size, thickness, material, as well as brand and manufacturer to ensure that you choose the best knife for your production needs. By carefully comparing and evaluating the different options, you can find the most cost-effective tool that best suits your production needs, resulting in increased productivity, reduced costs and improved product quality.

Later, We will continue to update information, and you can find more information on our website (passiontool.com) blog.

Of course, you can also pay attention to our Official social media:

Post time: Oct-25-2024