Selecting the appropriate material for your blades can frequently lead to confusion. In the end, the key lies in the blade's intended function and the essential characteristics it possesses. The focus of this article is on Tungsten, a widely used material, examining its characteristics, applications, and the general efficacy of tungsten blades.

In the Periodic table, tungsten holds the 74th position. Ranking among Earth's most potent metals, it boasts the greatest melting point among all metals, reaching a temperature of 3,422°C!

Its softness allows for cutting with just a hacksaw, leading to Tungsten's frequent use as an alloy. Merged with various metals to leverage their individual physical and chemical characteristics. Alloying Tungsten offers advantages in terms of heat resistance and toughness, while also enhancing its usability and applicability across a wider spectrum of uses. Tungsten Carbide ranks as the predominant Tungsten alloy. This compound, created by blending Tungsten powder and powdered Carbon, exhibits a hardness rating of 9.0 on the Mohs scale, akin to a diamond's hardness level. Additionally, the melting point of the Tungsten Carbide alloy is remarkably high, reaching 2200°C. Consequently, Tungsten Carbide enjoys broader usage than Tungsten in its unadulterated state, owing to its Tungsten characteristics and the additional advantages of Carbon.

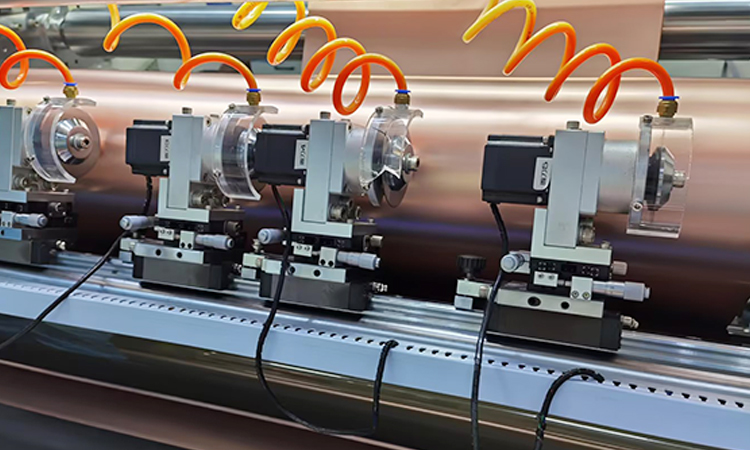

Tungsten Carbide blade, known for its exceptional resistance to heat and scratches and its long-lasting nature, is predominantly utilized in industrial cutting tools like machine knives. The industry has employed Tungsten Carbide blade for nearly a hundred years. In this instance, the Tungsten Carbide blade is repeatedly employed to precisely shape and cut. In this case, Tungsten Carbide has been selected as the most suitable and optimal material. The device's robustness and ability to withstand wear enable it to slice complex shapes multiple times without sustaining any harm.

In general, tungsten carbide blades have a wide range of applications in many fields, especially for machining hard materials and high-precision parts.

Post time: Jan-26-2024