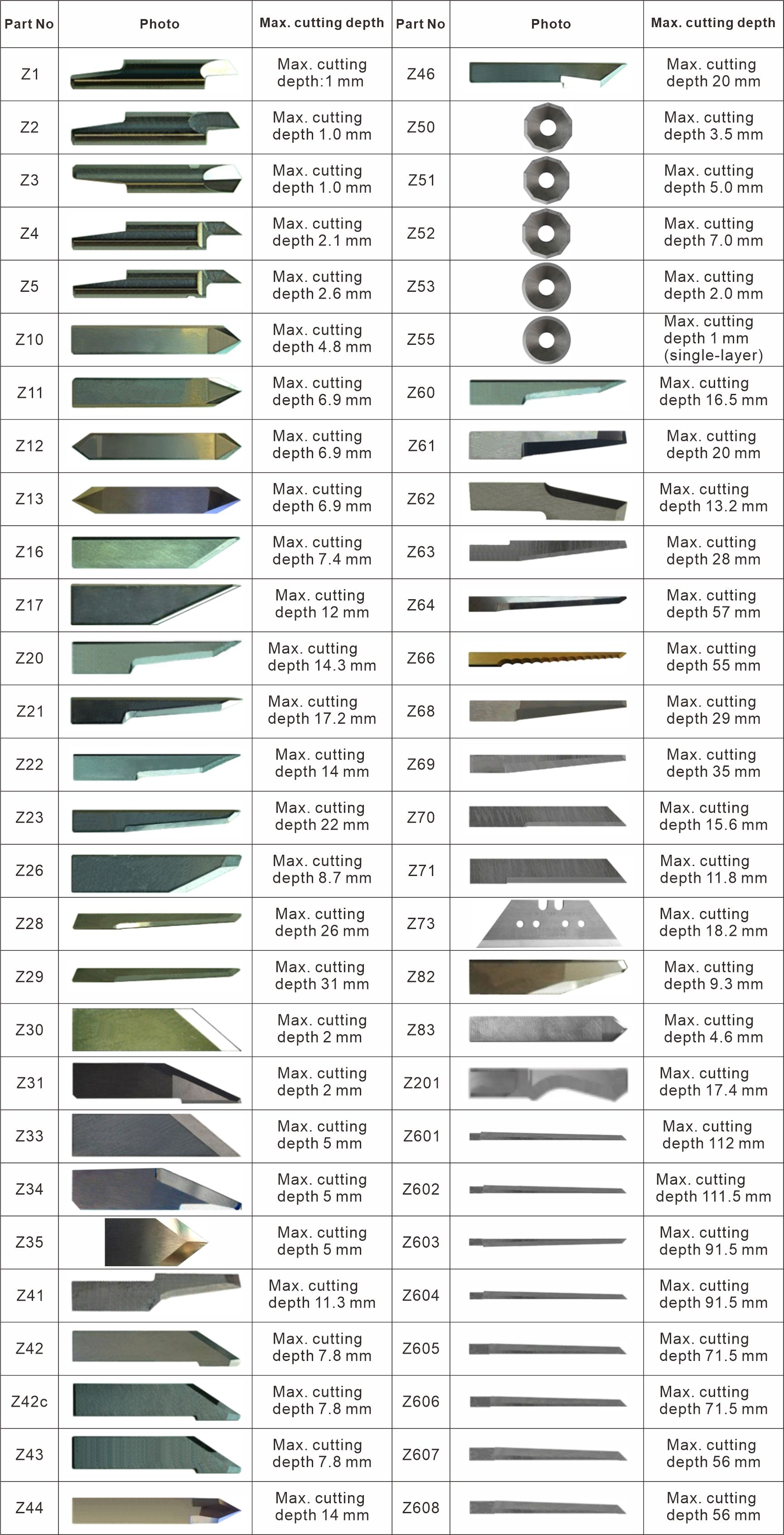

Tungsten carbide foam cutting knife vibration cutter zund z42 3910324 blade

Product introduction

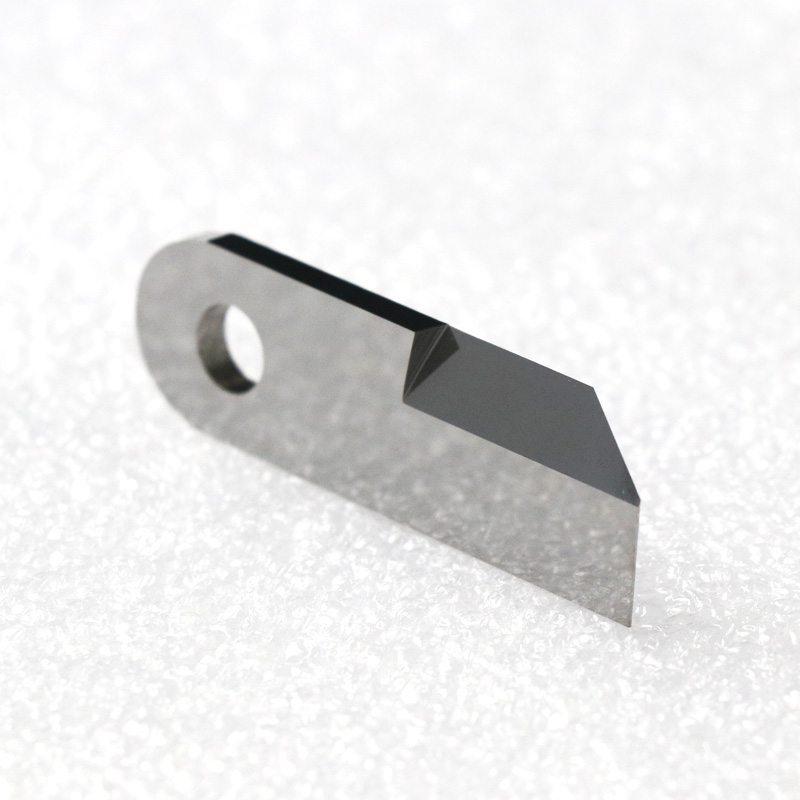

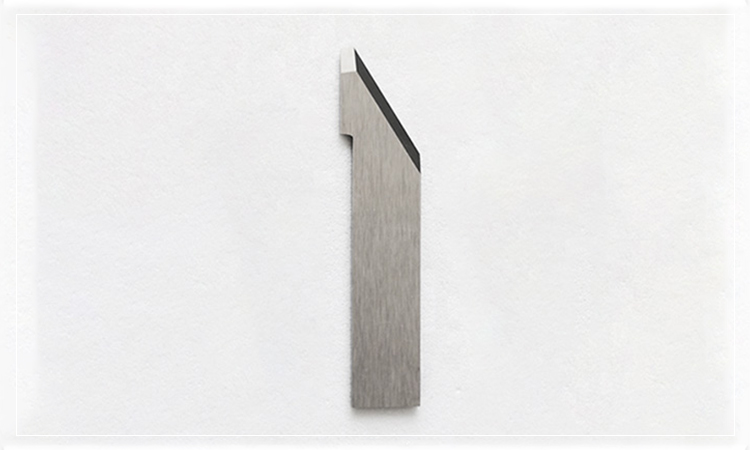

This high quality generic set of 2 blades is suitable for Zund S3, G3 & L3 digital cutters using EOT and POT tool heads. These flat oscillating blades with small pre-cut have a cutting angle of 55°and a maximum cutting depth of 7.8 mm. These blades are suitable for woven materials, textiles, leather and corrugated cardboard. These high quality generic blades correspond to Zund part number 3910324, also called Z42 blades.

Advantages of our Zund Magnetic Blades:

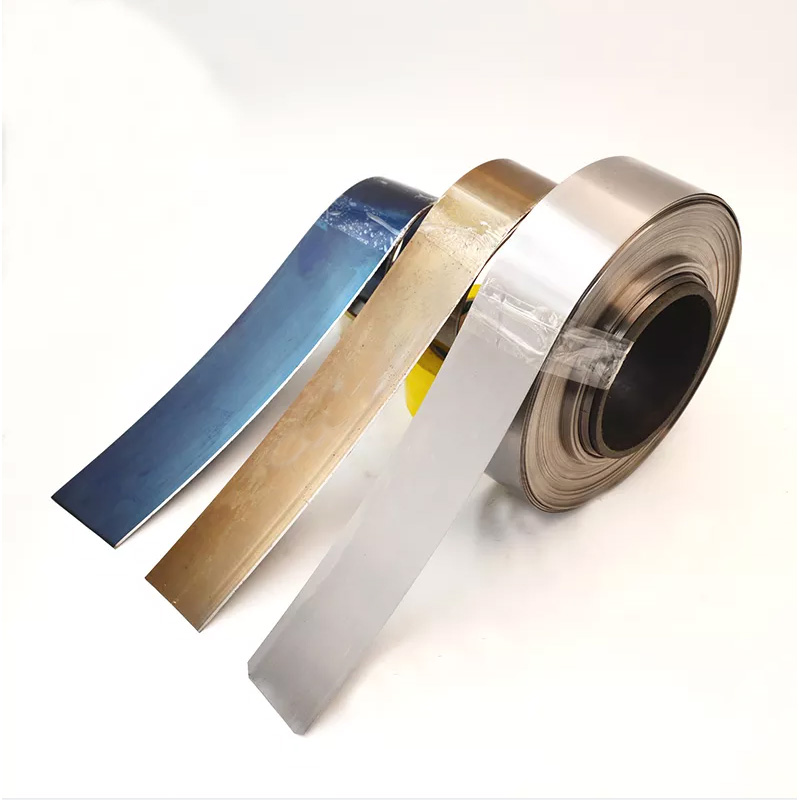

1.Material of Solid Tungsten Carbide YG8X, YG10X, YG12X etc, excellent material to produce Plotter/Digital cutters' blades & knives.

2.High hardness, super cutting quality, durable sharpness, long lifespan.

3.Competitive price, well accepted by our customers.

4.Availability in stock, blades can be sent to our customers in a short time.

5.Door to Door, fast and convenient delivery service, provided by DHL, FedEx, UPS, TNT, EMS etc.

6.OEM service is always available. Please feel free to tell us the requirement and specification of your company. If you are interested in having your company's own blades/knives, please send us the drawings and dimensions, so that we can reply you with the accurate quotation. Thank you.

Product Application

They are ideal to cut leather , carton boards,doubling plate,composite material,paper,textile,packaging material ,frame,sponge,plastic ,medical products,filter,Skiing material,cable etc different material .

Product Parameter

| Product Nume | ZUND Blades Z42 |

| Material | Tungsten Carbide |

| Blade thickness | 0.63 mm |

| OEM | Max. cutting depth 7.8 mm |

| Properties | Robust oscillating knife with small pre-cut. |

| Application | Canvas, Foam board, Folding Carton, Gasket materials, Magnetic foil, Paper, Polyester fabric, PVC, Reflective vinyl film, Self-adhesive vinyl film |

| Replacement | Yes |

About Factory

Chengdu PASSION precision tools Co., Ltd committed to providing customers with the best solutions according to their different requirements. We can design blades according to customer's purpose, including cutting edge, drawings and other details. And try our best to provide customers with the best solution. We can also customize blades for customers according to customer drawings and details of blades, and follow up with customers to select the most suitable materials to manufacture products for customers.