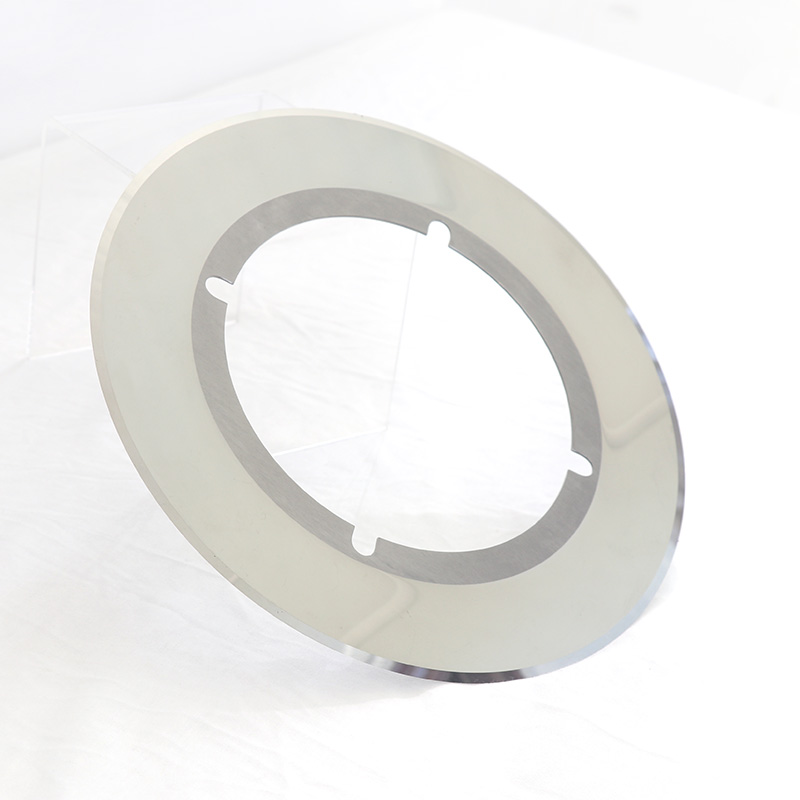

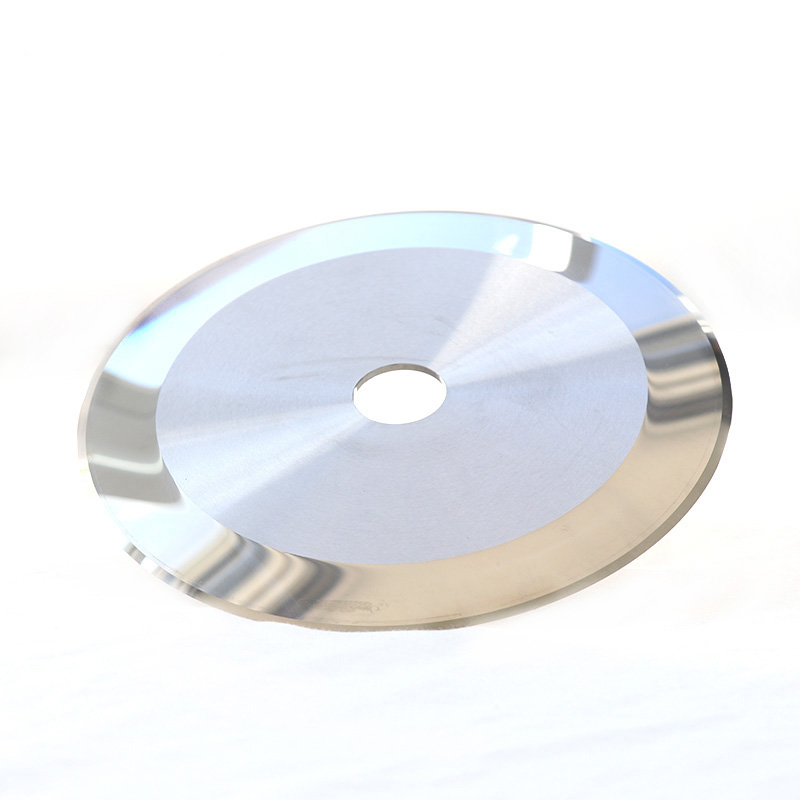

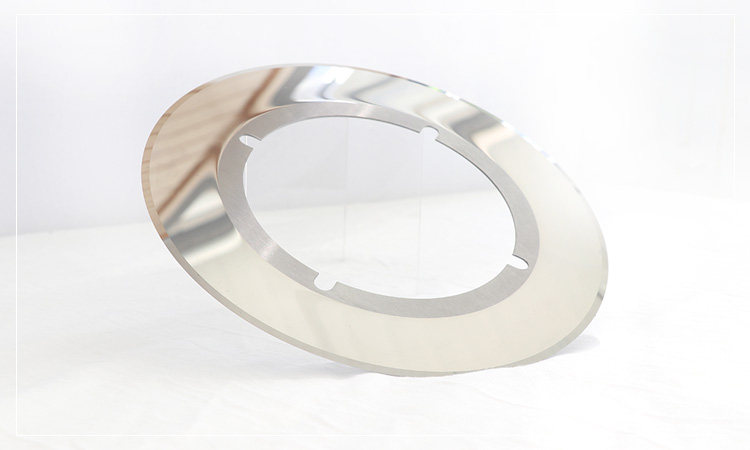

Tungsten Carbide Fosber Knives Slitting Circular Blades For Corrugated Cardboard Cutting

Product Introduction

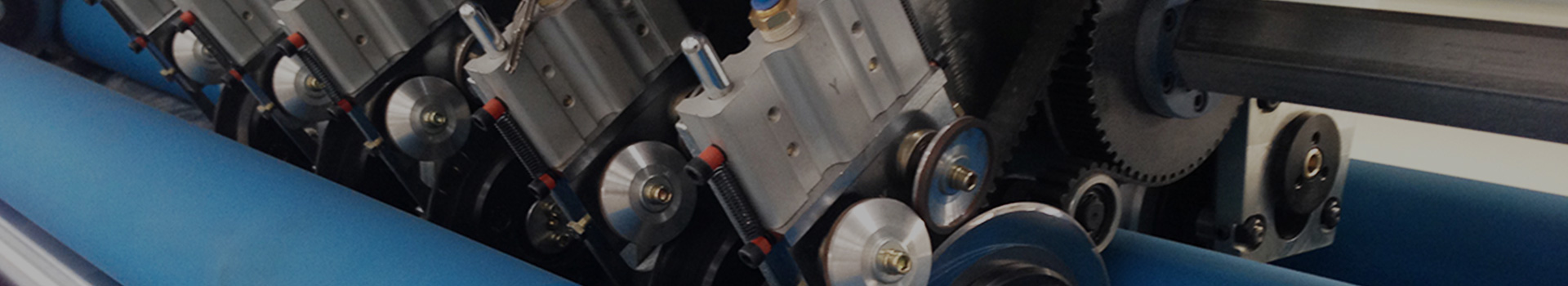

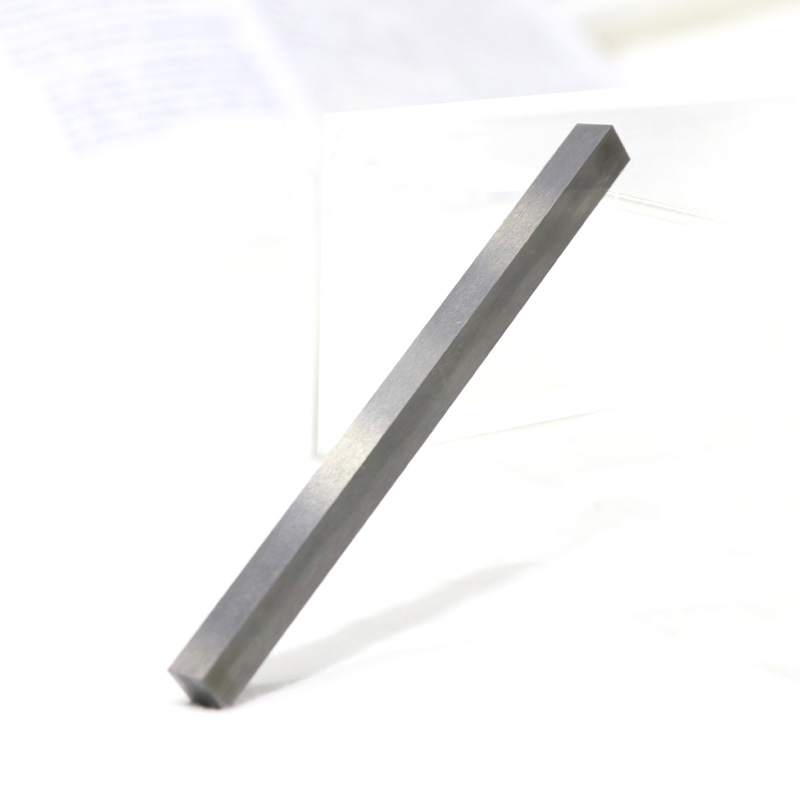

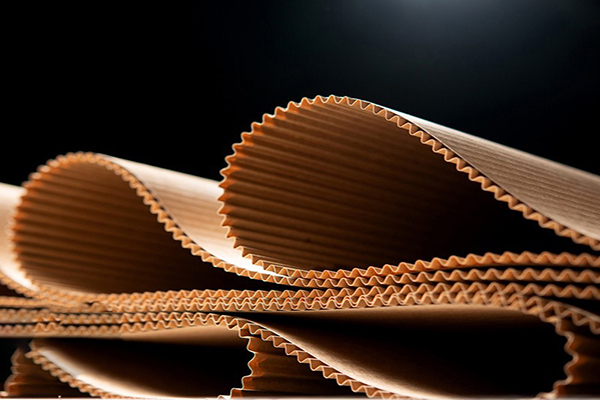

Corrugated slitter scorers, or corrugated board slitting machines, are used to slit corrugated boards into the proper shape, preparing for further processing. Fast positioning and precision cutting of the slitter scorers and blades during high operation speeds are of great importance. Tungsten carbide, or cemented carbide, is the ideal material of choice for manufacturing corrugator slitter knives thanks to its toughness and wear & impact resistance, resulting in high precision cutting and long service life.

1.100% virgin materials;

2.Micro-grain tungsten carbide;

3.Outstanding hardness and toughness;

4.Excellent wear and impact resistance;

5.Result in a clean-cut finish;

6.Extreme durability and extended service life;

7.Maximize performance;

8.Minimize downtime;

9.Varied sizes are available.

Specifications

| Product Nume | FOSBER corrugated cardboard blade | Size | Φ230*Φ135*1.1 mm |

| Material | Tungsten carbide | Type | Circular knife, Round knife |

| Place of Origin | SiChuan, China | Material | Tungsten Carbide;100% Virgin Raw Material |

| Package | 5 pcs/carton, 10 pcs/carton, custom packing | Customized support | OEM, ODM |

Common sizes for high speed machine

|

Dimension(mm) |

ID(mm) |

OD(mm) |

Thickness(mm) |

Machine Brand |

|

Φ300*Φ112*1.2 |

Φ112 |

Φ300 |

1.2 |

TCY |

|

Φ291*Φ203*1.1 |

Φ203 |

Φ291 |

1.1 |

FOSBER |

|

Φ280*Φ202*1.4 |

Φ202 |

Φ280 |

1.4 |

Mitsubishi |

|

Φ280*Φ160*1.0 |

Φ160 |

Φ280 |

1.0 |

Mitsubishi |

|

Φ280*Φ168*1.4 |

Φ168 |

Φ280 |

1.4 |

K&M |

|

Φ260*Φ168.3*1.2 |

Φ168 |

Φ260 |

1.2 |

Marquip |

|

Φ260*Φ140*1.5 |

Φ140 |

Φ260 |

1.5 |

lsowa |

|

Φ265*Φ112*1.4 |

Φ112 |

Φ265 |

1.4 |

Oranda |

|

Φ260*Φ112*1.4 |

Φ112 |

Φ260 |

1.4 |

Oranda |

|

Φ260*Φ168.27*1.2 |

Φ168.27 |

Φ260 |

1.2 |

Hooper/Simon |

|

Φ250*Φ150*0.8 |

Φ150 |

Φ250 |

0.8 |

Peters |

|

Φ244*Φ222*1.0 |

Φ222 |

Φ244 |

1.0 |

Hooper |

|

Φ240.18*Φ31.92*1.14 |

Φ31.92 |

Φ240.18 |

1.14 |

BHS |

|

Φ240*Φ32*1.2 |

Φ32 |

Φ240 |

1.2 |

BHS |

|

Φ240*Φ115*1.0 |

Φ115 |

Φ240 |

1.0 |

Agnati |

|

Φ230*Φ110*1.1 |

Φ110 |

Φ230 |

1.1 |

FOSBER |

|

Φ230*Φ135*1.1 |

Φ135 |

Φ230 |

1.1 |

FOSBER |

|

Knife edge type: Single or double side available. Materials: Tungsten Carbide or customization Materials. Application: For corrugated paperboard industry, for cutting tobacco, paper cutting, film, foam, rubber,foil, graphite and so on. |

||||

|

NOTE: Customization available per customer drawing or actual sample |

||||

Using Scenes

FOSBER is a famous brand of corrugated machinery in Italian. We have been making FOSBER Slitting blades for 15 years. We have rich experience in the blade production of high-speed machines. we have been focusing on the production and manufacture ofcemented carbide tools, always pursuing innovation and breakthroughs, andconstantly optimizing the supply chain system.Our blades common size is Φ230*Φ135*1.1 mm.

Our precision ground tungsten carbide blades result in a sharp, clean-cut finish, which also prevents deformation of the corrugated board structure. And because of their extreme durability, our tungsten carbide slitting knives are superior in situations where other knives would wear out quickly, such as in large production runs. This reduces the number of blade grinding intervals, increasing both productivity and the service life of your slitter knives.

About Factory

Chengdu PASSION Precision Tools Co., Ltd team have more than 20 years' manufacturing and exporting experience on verious kinds of carbide knives. We offer all kinds of technical guidance and drawing design for free. "Passion" focus on TCT knives with improved durability and wear-life, up to 500% to 1000% better than standard steels. Passion's professional factory services and cost-effective products can help you to get more orders from your customers. We sincerely invite agents and distributors from various countries. Contact us freely.

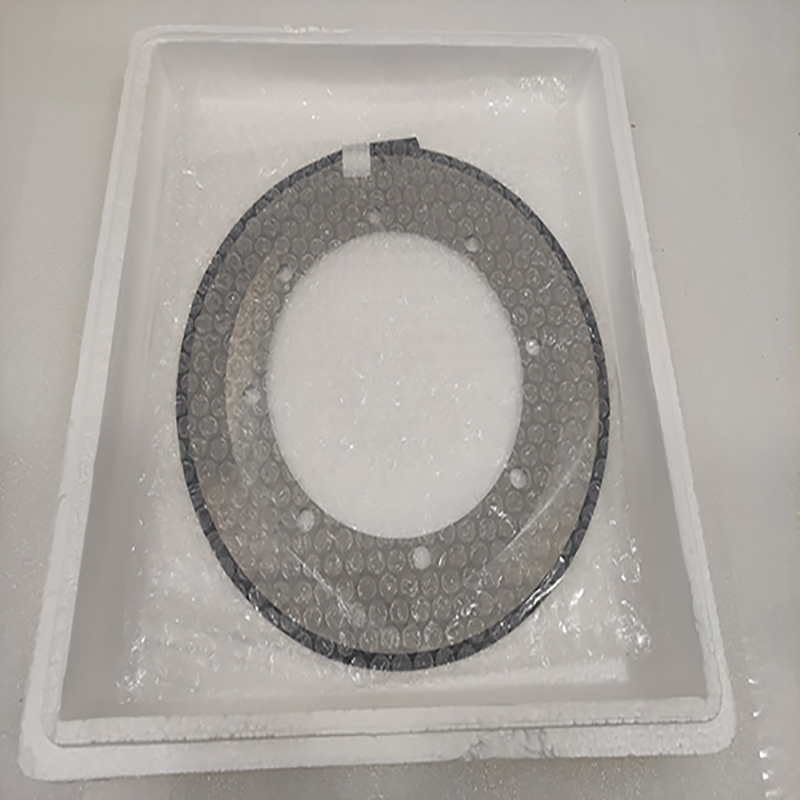

About packing

Type 1:Blade is packed with a bubble pack, and rubber protector of cutting edge, then packed with foam pads in carton box.

Type 2:Blade with rubber protector of cutting edge is vacuumed to the cardboard, and then pack it in a single carton, then10 pcs max in one carton case.