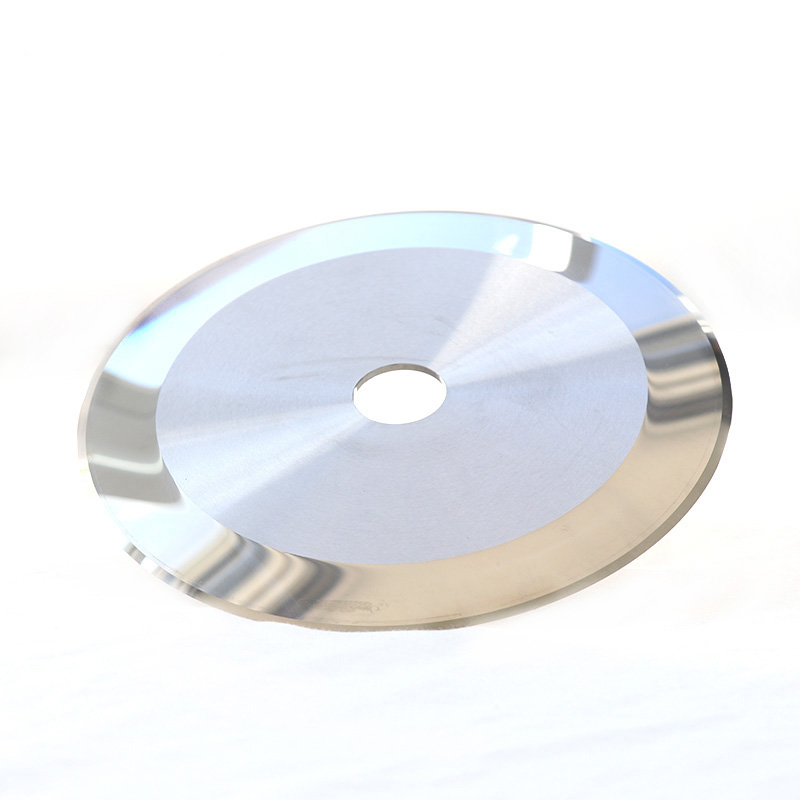

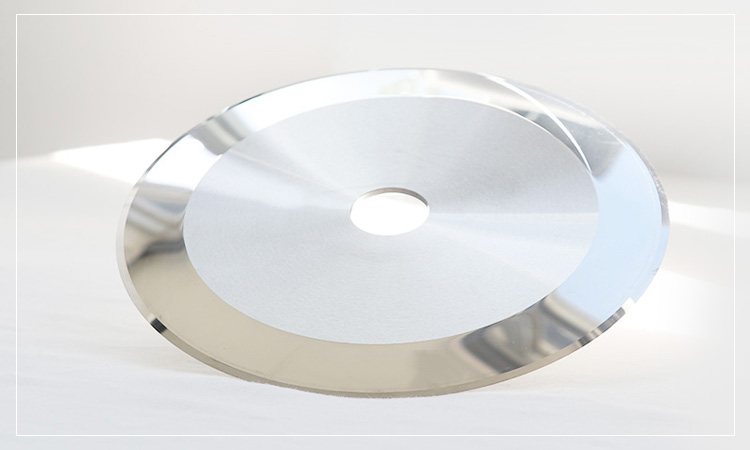

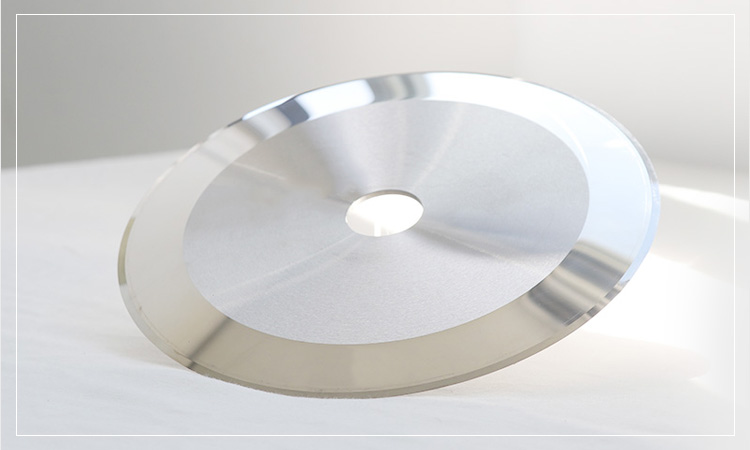

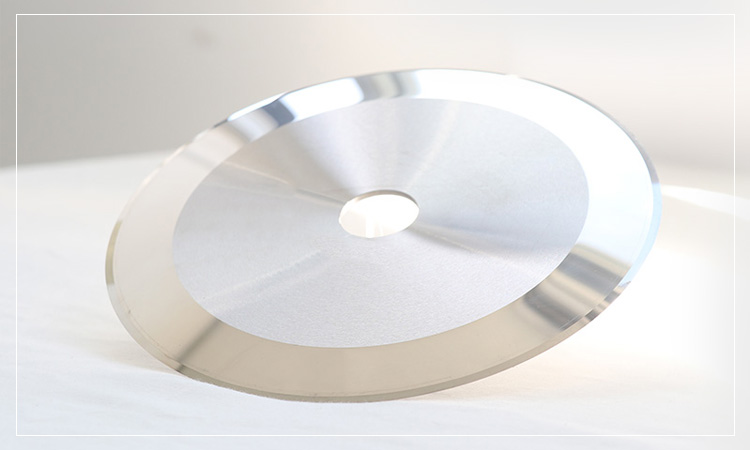

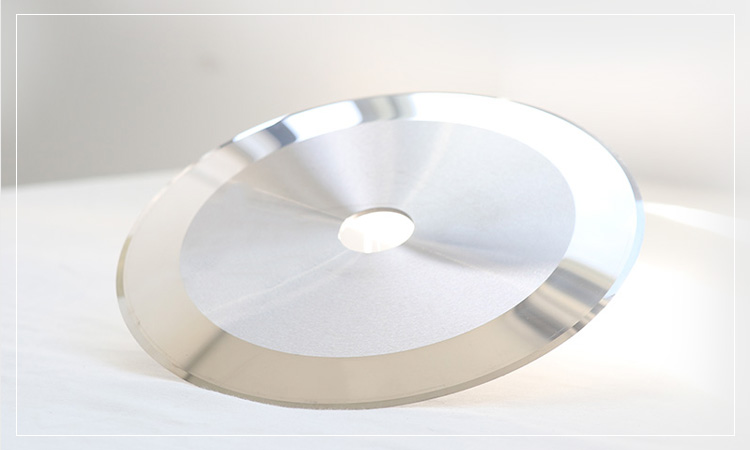

Tungsten Carbide industrial knife tape cutter circular blades

Product Features

1.Superior quality:Blade adoption stain and YG12X tungsten carbide and other materials.It has good toughness and higher hardness,excellent technology.

2.Sharp:Vacuum quenching more uniform hardness greatly improved strength and toughness of blades.

3.High-precision:Adopt a variety of professional imported CNC machine tools and high precision cutting to ensure the sharpness and accuracy of the cutting edge.

4.Product warranty:Quality assurance professional manufacturing.

5.Two kinds of knife edges:Large blade double-layer is due to the large slope of the blade,therefore the cutting resistance is smaller and the incision is more flat.No burr.The small double blade is commonly used at present.It is mainly used for cutting hard or thick materials,such as adhesive,paper,leather,etc.

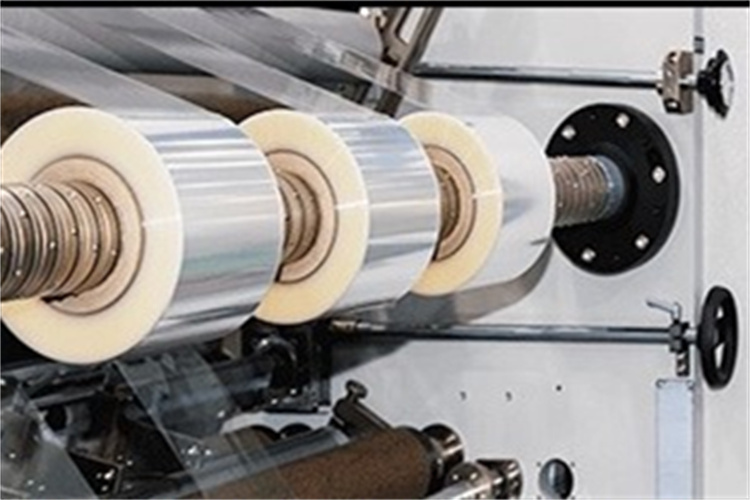

Product application

Some Applicable Industrial

Metal cutting、Tape cutting 、Film cutting、Medical material cutting、Paper cutting、Chemical fiber cutting、Fabric slitting、Nonwoven slitting、Aluminum foil cutting

Product description

| product name | Circular Blades |

| Material | Tungsten Carbide |

| Packaging Details | Composite Board |

| Port | Chengdu |

| Grade | YG12X |

| Condition | New |

| After-sales Service | Video Support |

Common sizes

| No. | Sizes | Material |

| 1 | Φ150*Φ25.4*2 |

Inlaid TC |

| 2 | Φ160*Φ25.4*2 | |

| 3 | Φ180*Φ25.4*2 | |

| 4 | Φ180*Φ25.4*2.5 | |

| 5 | Φ200*Φ25.4*2 | |

| 6 | Φ250*Φ25.4*2.5 | |

| 7 | Φ250*Φ25.4*3 | |

| 8 | Φ300*Φ25.4*3 |

FAQ

| No. | Sizes | Material |

| 1 | Φ150*Φ25.4*2 |

Inlaid TC |

| 2 | Φ160*Φ25.4*2 | |

| 3 | Φ180*Φ25.4*2 | |

| 4 | Φ180*Φ25.4*2.5 | |

| 5 | Φ200*Φ25.4*2 | |

| 6 | Φ250*Φ25.4*2.5 | |

| 7 | Φ250*Φ25.4*3 | |

| 8 | Φ300*Φ25.4*3 |

Packaging Details

Q1: Are you trading company or manufacturer ?

A1: Our factory is a professional manufacturer of machinery blades for more than 20years.Our blades are mainly used in: packaging, paper, rubber, optoelectronics, electronics, light industry, printing, metallurgy, and other machines.

Q2: what is your blade hardness?

A2: Different material has different hardness, from 48HRC to 68HRC, we both have. You can advice the function of your blade, we can provide suitable suggestion for you.

Q3: What is your advantage if I choose you?

A3: 1. End manufacturer with competitive factory price.