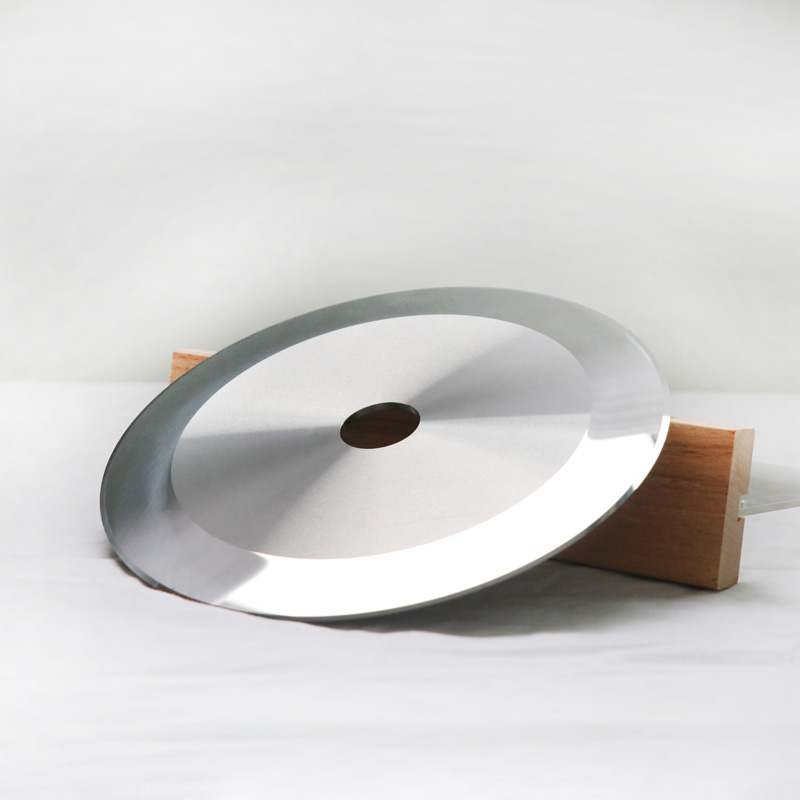

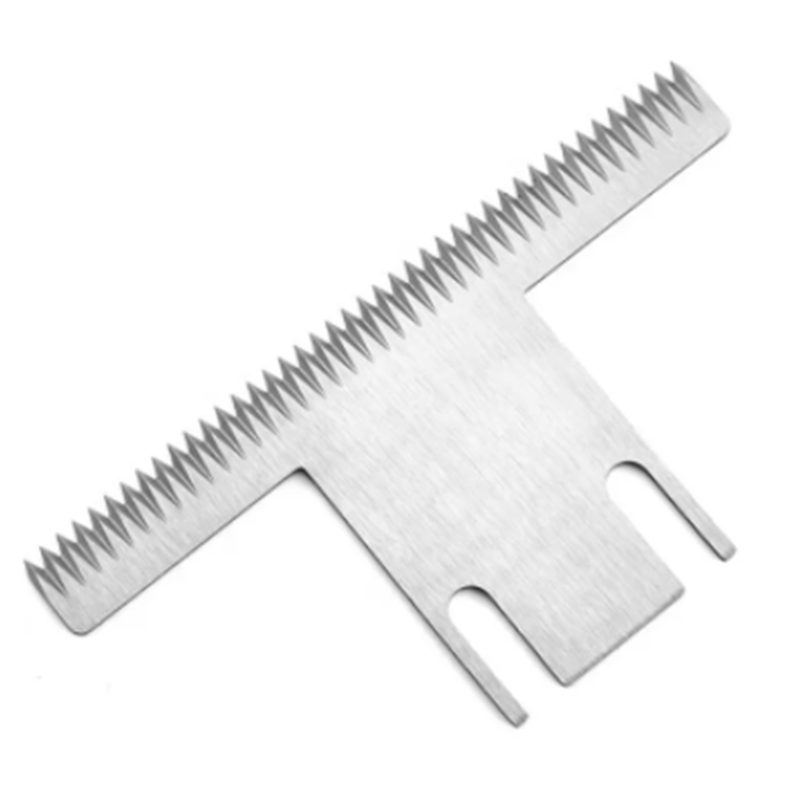

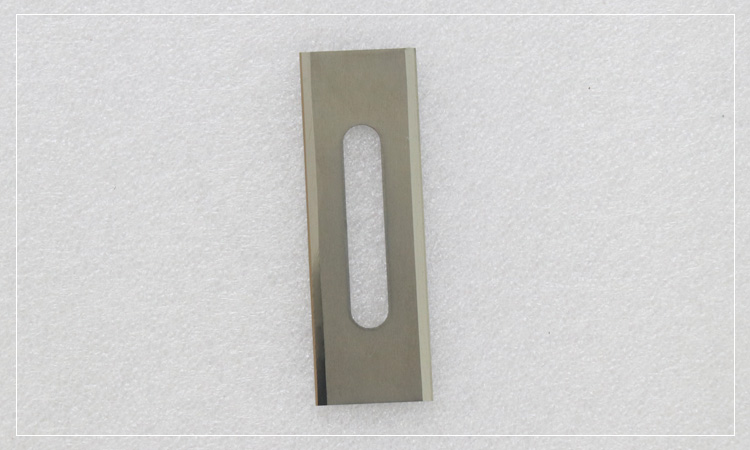

Tungsten Carbide Industrial Thin Knife Blade For Chemical Fiber Cutting

Product Introduction

1. Fine Porosity Would Be Remained In Powder Metallurgy Of Processing For Tungsten Carbide, Which Will Be The Beginning Of Destroy Of Products.

2. To Remove This Fine Porosity, We Passion Produce Products Through Hip Process.

3. This Process Is Progressed Under The High Temperature And Pressure, And Put The Identical Pressure On Whole Surface Of Product.

4. At This Time, a Fine Porosity Would Be Removed, And Effected On Improving High Strength.

Specifications

| Product Nume | Chemical Fiber Blade | Thickness | 0.4 Mm |

| Blade Materials | Tungsten Carbide Materials | Carbide Grade | YG12X |

| Usage | Fiber | Logo | Accept Customized Logo |

| Blade Sizes | 57*19*0.4 Mm | Customized Support | OEM, ODM |

Common sizes for high speed machine

|

No. |

Common Size(mm) |

|

1 |

193*18.9*0.884 |

|

2 |

170*19*0.884 |

|

3 |

140*19*1.4 |

|

4 |

140*19*0.884 |

|

5 |

135.5*19.05*1.4 |

|

6 |

135*19.05*1.4 |

|

7 |

135*18.5*1.4 |

|

8 |

118*19*1.5 |

|

9 |

117.5*15.5*0.9 |

|

10 |

115.3*18.54*0.84 |

|

11 |

95*19*0.884 |

|

12 |

90*10*0.9 |

|

13 |

74.5*15.5*0.884 |

| Note:Customization available per customer's drawing or sample | |

Using Scenes

Used in film, chemical fiber, textile, tape, paper, aluminum foil cutting; leather trimming, etc. (OPP, BOPP film, PET film, composite film, aluminized film, laser film, stretch film, pearl film, cast film , lithium battery film, tape master roll);

Suitable for slitter machine, slitting machine, laminating machine, etc.

About Factory

Chengdu Passion Precision Tools Co., Ltd Committed To Providing Customers With The Best Solutions According To Their Different Requirements. We Can Design Blades According To Customer's Purpose, Including Cutting Edge, Drawings And Other Details. And Try Our Best To Provide Customers With The Best Solution. We Can Also Customize Blades For Customers According To Customer Drawings And Details Of Blades, And Follow Up With Customers To Select The Most Suitable Materials To Manufacture Products For Customers.